Rapid Injection Molding or RIM is the most vital process taken into use for ensuring speed and quality remain constant for the duration of manufacturing. It is the most vital process that is required for critical design considerations – encountered for the duration of this molding process. If compare to traditional molding, rapid injection molding is the way that lead to faster and cost-effective tooling. Injection mold tooling china this tooling process is commonly required for different industry verticals that you can get in just a few clicks by reaching at NICE-Rapid Tooling. We have state of the art manufacturing units and spaces to ease the process.

Rapid Injection Molding or RIM is the most vital process taken into use for ensuring speed and quality remain constant for the duration of manufacturing. It is the most vital process that is required for critical design considerations – encountered for the duration of this molding process. If compare to traditional molding, rapid injection molding is the way that lead to faster and cost-effective tooling. Injection mold tooling china this tooling process is commonly required for different industry verticals that you can get in just a few clicks by reaching at Vowin-Rapid Tooling. We have state of the art manufacturing units and spaces to ease the process.

If you are looking for the right solutions for Rapid injection molding, you will have some better options to fulfill your requirement by going online that is counted as one of the convenient and ideal ways to enhance your experience. At Vowinn-Rapid Tooling, you will get precise solutions for rapid injection molding that allows making prototype injection mold china parts in a production thermoplastic resin. You can use them for final sign off, full functionality, fit testing and sales launches that need no error in the molding systems you are looking for.

Vowin Rapid has been using the right technologies to work on both low and medium volume production runs that depend on your project requirement. They have years of experience and proven track record of offering you something advanced and innovative that will surely enhance your experience and provide you the right ways. Our team of engineers and prototype experts has experience enough and expertise in Rapid injection molding. Whether you are looking for aluminum and soft tool-steel tooling for the production of high quality low to medium volume parts or anything else, you will get the right solutions from experts. Rapid injection molding solution provided by us is second to none. We are here to endow you with affordable price and competitive solutions for all your production and prototype requirements. We are here offering you surface finishing services too.Feel free to contact us either by giving a call or sending a mail and get the right rapid injection molding solutions and services.

Rapid injection moulding allows us to make prototype injection moulded parts in a production thermoplastic resin. These parts may be used for final sign off, full functionality, fit testing and sales launches.

Vowin Rapid is used to working on both low and medium volume production runs, depending on your project requirements. Through our many years of experience, we have achieved expertise in the rapid manufacture of aluminium and soft tool-steel tooling for production of high quality low to medium-volume parts. We can provide highly price-competitve solutions for low to medium-volume production requirements for your business.

We provide various kinds of surface finishing services, including plating, painting, silk screening, pad printing and hot stamp printing.

Design for Manufacture (DFM)

Design for Manufacture is a helpful tool that we can provide to our customers to help minimise tooling costs and to help expedite the manufacturing process.

We will provide you with a detailed report that contains important information about your part design and highlights any potential problem areas.

In addressing design issues early on, the DFM helps to eliminate costly re-tooling or delays in the manufacturing process caused by a problematic part design.

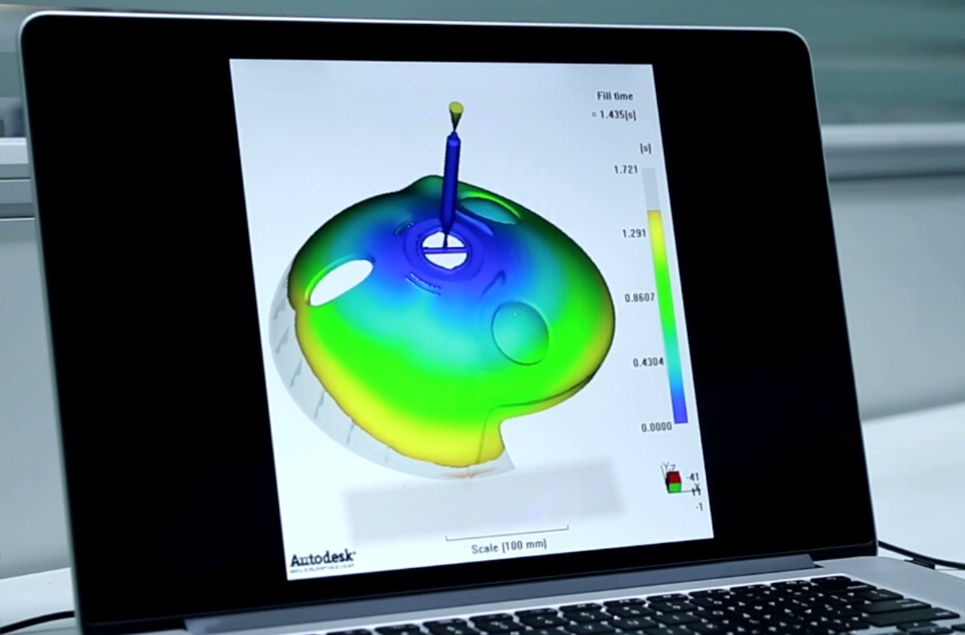

We also have the ability to provide mould flow analysis, which, when combined with the DFM, can save you money and ensure production in a timely manner.

Engineering and design services we provide: