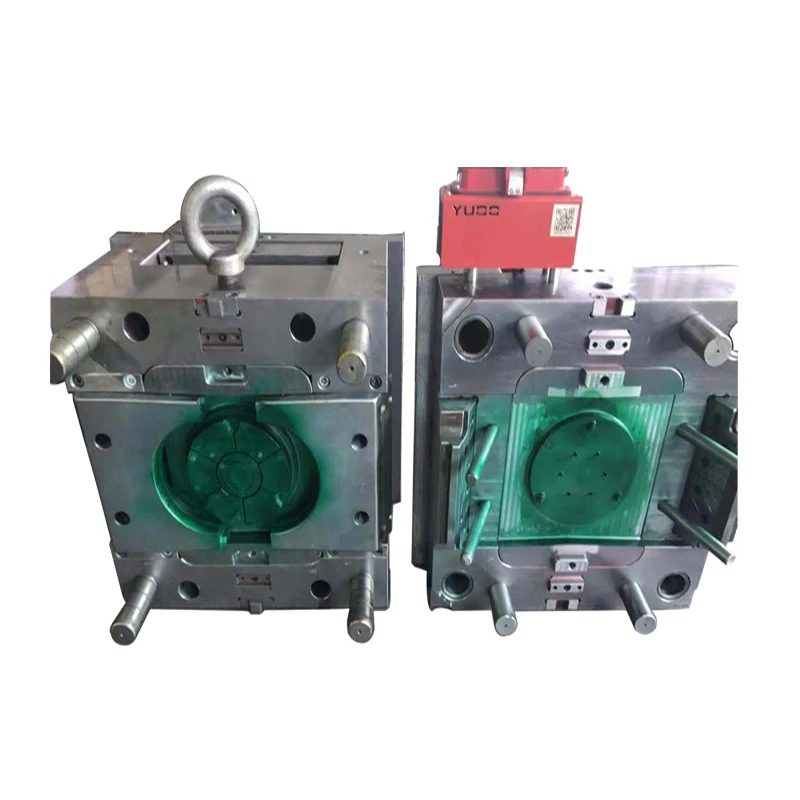

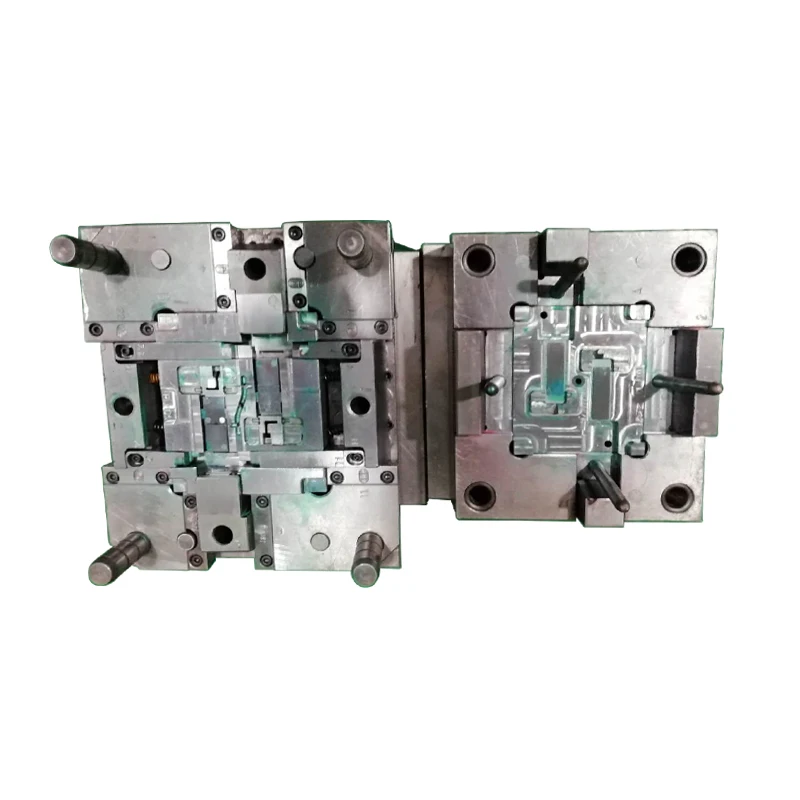

Mold product and press mold plastic injection mould mode high quality custom machining stamping dies for metal parts,Mould Battery Case Storage Holder Rechargeable Hard Plastic injection Mold,Hot sale injection plastic mold for household articles

Services:Industry design,mechanical design,mould design,manufacturing,second processing,assembly and etc.,one-stop services for plastic parts.

Products Range:Automotive Parts,Industrial Parts,Communication Parts,Household Appliances Parts,Electronics Parts,Cosmetics Parts,Computer Peripherals Parts,Medical Parts,Precision Parts,Equipment Parts...

Mold Type:In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould

Advantages:

1. Competitive Price

2. Quick Delivery time(2-4 weeks)

3. ISO Certificated with the srtictest quality control system

4. 23 Years OEM&ODM Mould-making and Plastic processing experience

5. Advanced equipment and Skilled workers

|

Item |

Description |

|

Core & Cavity Material |

H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80, or others by request |

|

Mould Base |

ASSAB, LKM, DAIDO, FUTABA |

|

Mould hardness |

HRC38-52,HB,H |

|

Mould Standard |

MISUMI, DME,CUMSA,HASCO |

|

Mould structure |

2 plates or 3 plates |

|

Mould life |

300,000 - 1,000,000 |

|

Part material |

all thermoplastics such as ABS, PC, PP, PE, PA, TPE, POM, PPS, PBT and other high engineering plastic, such as PEEK, PPS, PPO, PEI, PES etc |

|

Available format |

.stp/.pdf/.x-t/.step./.dwg/.dxf/.igs/.prt/.stl/.sldprt |