1. About our company 1) We have been doing professional plastic part and plastic parting products for 10 years, equipped with 30 sets mold processing equipment, proffessional CAD, CAM, CAE technology and special testing equipment. 2) 2012 three-star

1. About our company

1) We have been doing professional plastic part and plastic parting products for 10 years, equipped with 30 sets mold processing equipment, proffessional CAD, CAM, CAE technology and special testing equipment.

2) 2012 three-star mold Factory.

3) Our die include: auto parts, household appliances, medical equipment, House application products, electronic and electrical appliances, handicrafts and engineering construction etc...

4) We will Quote you our best price on time, please provide detailed information when send inquiry.

5) please inform the molding material, weight, annual purchase quantity, target completion time and other special requirements (eg: UV, VO, painting, chrome, screen printing, assembly and so on).

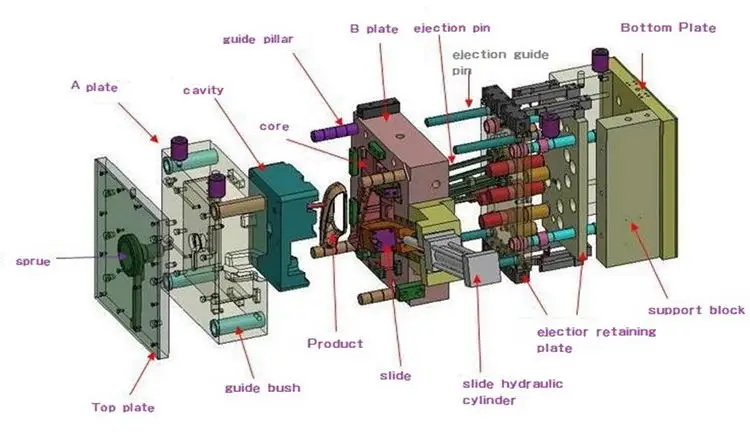

Plastic Injection Mould making

1.Samples/Drawing &Requirement from you

2.Mould design:we will Communicate and Exchange the opinion with you after you place order.

3.Material Purchase:Steel cutting and Mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling processing.

6.Mould testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

9.We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

Plastic molding Specification

1. Professional manufacturer,design,production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

|

We provide |

Mold ,phototype,product assembly,mold injection, surface printing |

| Mold Base | LKM, HASCO, DME or your requirementLKM, HASCO, DME or your requirement |

| Mold Materia | 45#, P20, H13, 718, 1.2344, 1.2738 and so on |

| Standard | HASCO, DME, MISUMI, PUNCH and so on |

| Product Materia | PC/ABS, ABS, PC, PVC, PA66, POM or other you want |

| Standard for Product Appearance for graining | MT(Mold Tech), YS, HN Series |

| Color Contrast for Plastic | RAL PANTONE |

| Design & program softwares | CAD/CAM/CAE,UG,PRO/E,Cimatron,Powermill,Solidworks,Catia,etc. |

| Processing equipment | CNC machine,Automotic lathe machine,EDM machine,Wire-cutting machine,Milling/Grinding machine,Punching/Drilling machine,Ultrasonec cleaning machine,etc. |

| Detection Equipment | Projector,Calliper,Height gauge,Screw gauge,Hardness gauge,etc. |

| Runner | Cold/Hot Runner |

| Gate Type | Side gate, Sub gate, Pin point gate, Edge gate etc |

| Mould Weight | 50kg-15Ton |

| Injection Machine Type | 80-1500Ton |

| Finish | Pitting the word, mirror finish, matte surface, striae |

| Main thechnology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

| Mould cavity | One cavity, multi-cavity or same different products be made together |