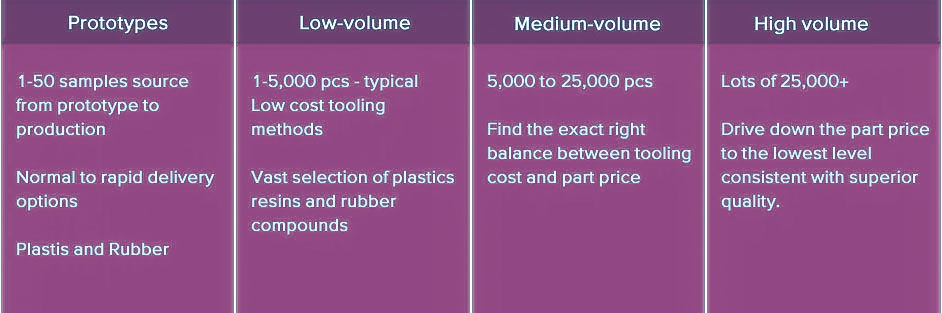

We make low to medium volume production in plastics, metals and silicones uniquely affordable. If you are looking for low to medium runs, then you have come to the right place! Our inexpensive rapid tooling for runs up to 100,000+ injection moulded parts may be exactly what you need. We continually invest in the latest equipment and rapid manufacturing technology and this, combined with our experienced staff, means that we are well equipped to handle low to medium-volume production programs.

We make low to medium volume production in plastics, metals and silicones uniquely affordable. If you are looking for low to medium runs, then you have come to the right place! Our inexpensive rapid tooling for runs up to 100,000+ injection moulded parts may be exactly what you need. We continually invest in the latest equipment and rapid manufacturing technology and this, combined with our experienced staff, means that we are well equipped to handle low to medium-volume production programs.

Low volume production of injection moulded parts is ideal for a few hundred up to thousands of parts of varying complexity. NICE Rapid’s affordable aluminum tooling or soft-tool steel tooling, makes it the most cost-effective method for this type of demand.

NICE Rapid minimises the “cost of waiting” for your full production tooling run and enables you to get to market quicker by having an aluminum or soft steel tool made within 3-30 days, (depending on product complexity and tool functionality).

Test your manufacturing or assembly processes with a pilot run prior to mass production to save time and money!