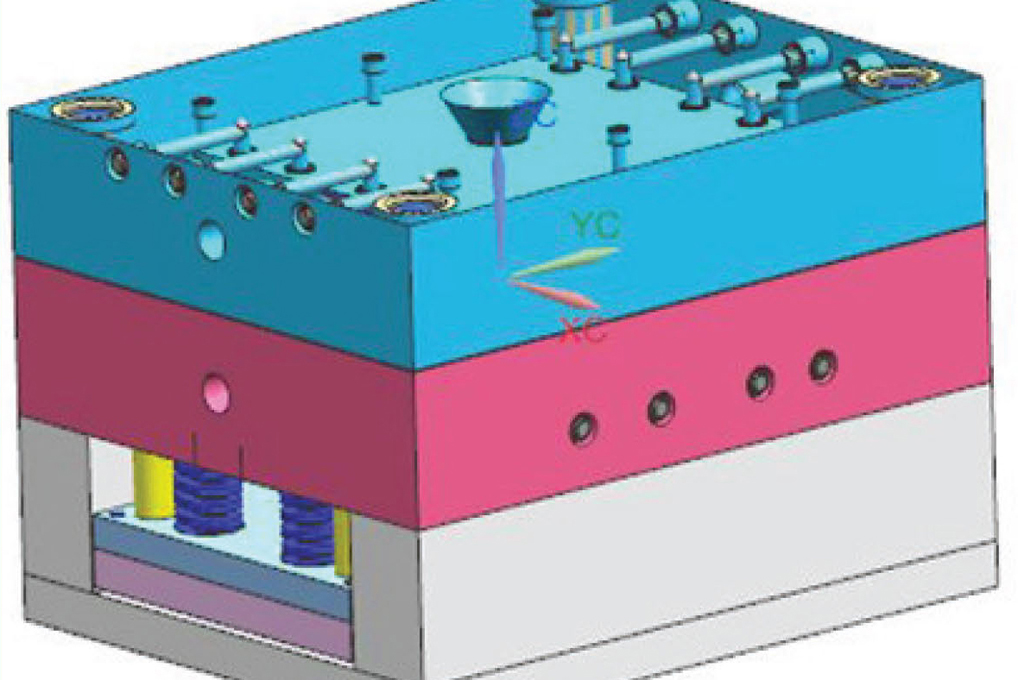

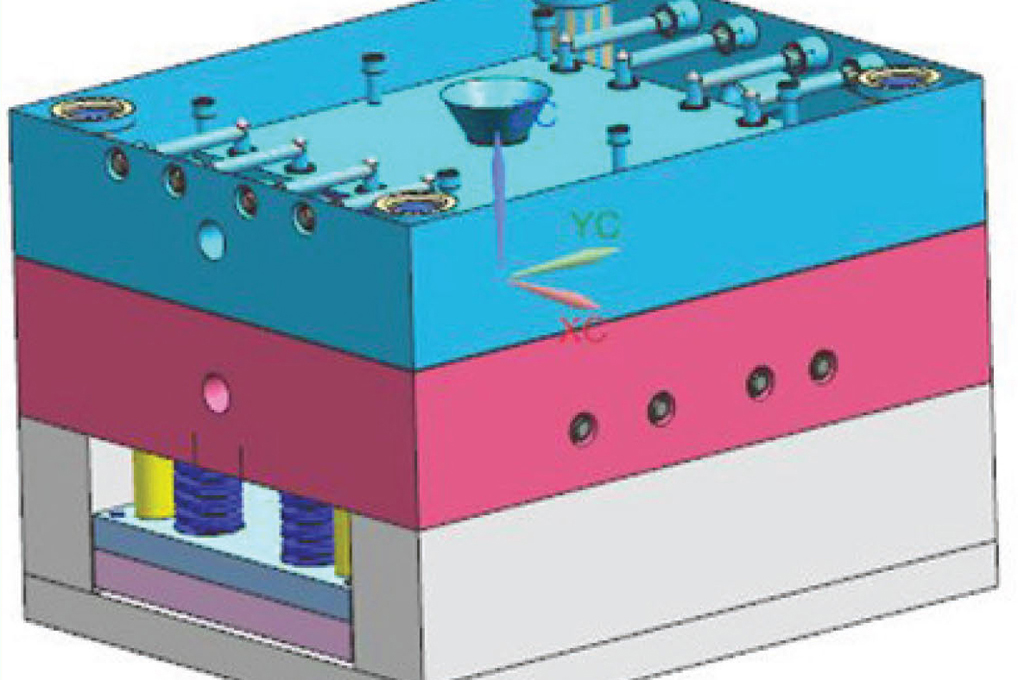

Overmold Rapid Tooling

ProtoTool & Injection Molding

PROJECT – Fabricate low-volume tooling and deliver 30 overmold parts to client for testing using the same material that will be used in eventual high-volume production tooling.

ISSUE – Very short time line of two weeks to fabricate two tools, runs parts and ship to client.

SOLUTION – Tight time line management and detailed communication to ensure no time is lost.

RESULT – Parts delivered to client within 12 days of client green lighting project. Part quality exceeded expectations.

Learn more below…

Project Summary

This project was the true definition of a rapid tooling project. Time line below:

RFQ – HLH receives an RFQ for 2 tools and parts. Recommendations to client by HLH is to make adjustments on radius and injection mold points – 1 Day.

DFM – Client reviews and accepts HLH recommendations per DFM report provided by HLH – 1 Day.

DAY 1 – Project starts, client confirms drawings and mold fabrication begins.

DAY 12 – HLH runs test parts and ships to client.

Day 14 – Client receives parts.

SERVICE: Rapid Tooling and Injection molding part run

QUANTITY: Tools – 30 Parts

MATERIALS: P20 & Aluminium MATERIALS PARTS: PP/GF30+SEBS

FINISHING: Straight From Mold

LEAD TIME: 14 Days

This project was a success because both parties communicated effectively and made decisions quickly.

Rapid projects require quick decisions to hit time lines. Decisions that are made need to be acted on same day.