Sheet metal bending galvanized stamping parts,Stainless sheet metal bending parts manufacturing,Modular switches sockets sheet metal stamping bending parts,Custom Punching Aluminum Sheet Metal U Shaped Bending Product,Bended sheet metal forming workin

Sheet metal bending galvanized stamping parts

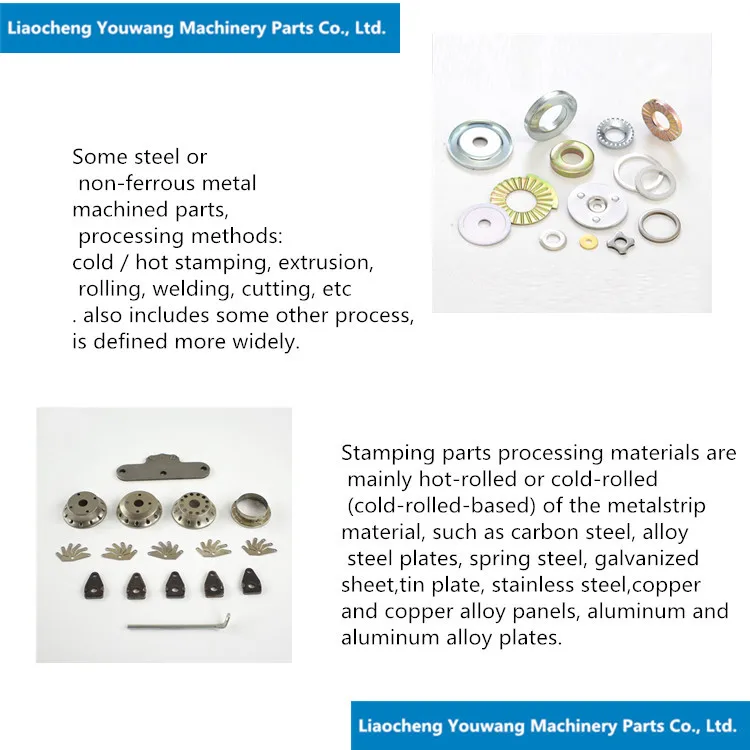

What is metal stamping parts?

|

Item Name |

metal stamping/metal stamping parts/stamped stainless steel |

|

Material |

Steel, stainless steel, carbon steel, aluminum, brass, etc. |

|

Machining type |

Laser cutting, CNC Milling, Turning, Milling, Drilling, threading, stamping, punching etc. |

|

Tolerance |

±0.05-0.1mm |

|

Surface finish |

Polished, powder coating, spray painting, HDG, Zinc plating,etc.

|

|

Major Equipments: |

--4000w Japanese AMADA Laser cutting machine --AMADA NCT punching machine --3 AMADA bending machines --TIG/MIG welding machines --Spot welding machines --Stamping machines --Oil hydraulic press --Riveting machine --Pipe cutting machine --Drawing mill --Powder coating line --High temperature drying oven |

|

OEM/ODM service |

Professional OEM/ODM service are available |

|

FOB Port |

Qingdao or any port of China |

|

Payment terms |

T/T,L/C Western Union, or other |

|

Production capacity |

500 Tons per month |

|

Delivery time |

14-30 Working days after order confirmation. |

|

Min. order quantity |

Negotiable |

|

QC System |

100% inspection before shipment |

|

Packing Methods |

1.Standard export package. |

|

2.As per customers' requirements, packaged in perfect condition. |

|

|

Remarks |

All metalworks are not in stock, customization only! (CAD, PDF,etc) for quotation. |

|

Located at Liaocheng,China. We are specialized in providing sheet metal fabrication oem service. According to your requests and drawings,either small or large quantity is acceptable for us. |

|

What is metal stamping parts?

|

Item Name |

metal stamping/metal stamping parts/stamped stainless steel |

|

Material |

Steel, stainless steel, carbon steel, aluminum, brass, etc. |

|

Machining type |

Laser cutting, CNC Milling, Turning, Milling, Drilling, threading, stamping, punching etc. |

|

Tolerance |

±0.05-0.1mm |

|

Surface finish |

Polished, powder coating, spray painting, HDG, Zinc plating,etc.

|

|

Major Equipments: |

--4000w Japanese AMADA Laser cutting machine --AMADA NCT punching machine --3 AMADA bending machines --TIG/MIG welding machines --Spot welding machines --Stamping machines --Oil hydraulic press --Riveting machine --Pipe cutting machine --Drawing mill --Powder coating line --High temperature drying oven |

|

OEM/ODM service |

Professional OEM/ODM service are available |

|

FOB Port |

any port of China |

|

Payment terms |

T/T,L/C Western Union, or other |

|

Production capacity |

500 Tons per month |

|

Delivery time |

14-30 Working days after order confirmation. |

|

Min. order quantity |

Negotiable |

|

QC System |

100% inspection before shipment |

|

Packing Methods |

1.Standard export package. |

|

2.As per customers' requirements, packaged in perfect condition. |

|

|

Remarks |

All metalworks are not in stock, customization only! (CAD, PDF,etc) for quotation. |

|

Located atChina. We are specialized in providing sheet metal fabrication oem service. According to your requests and drawings,either small or large quantity is acceptable for us. |

|