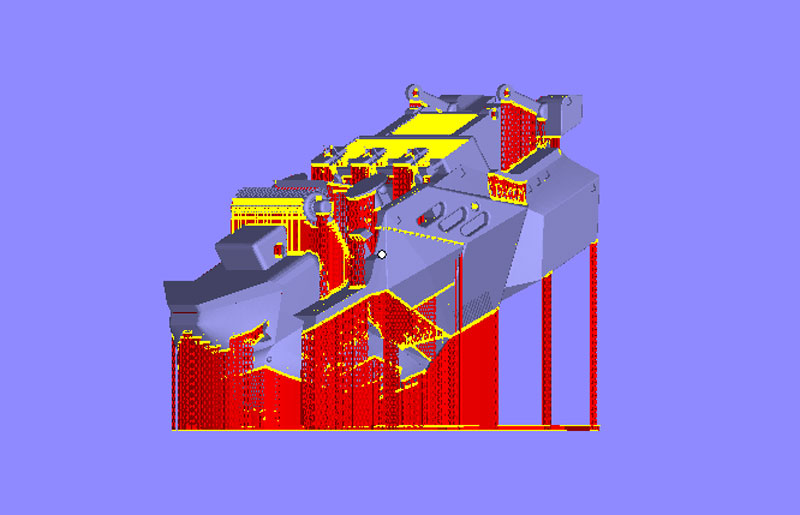

Project Name: Highway Inspection & Emergency Treatment Engineering Vehicle Concept Car Model

Designer: Department of Product Design, School of Arts and Crafts, Fuzhou University

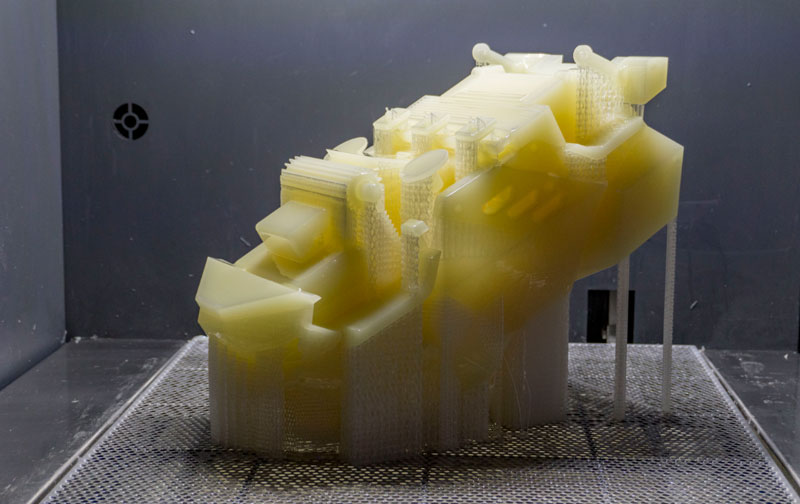

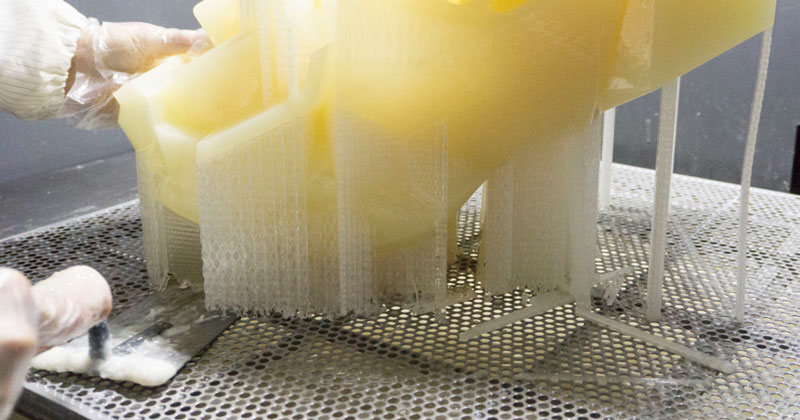

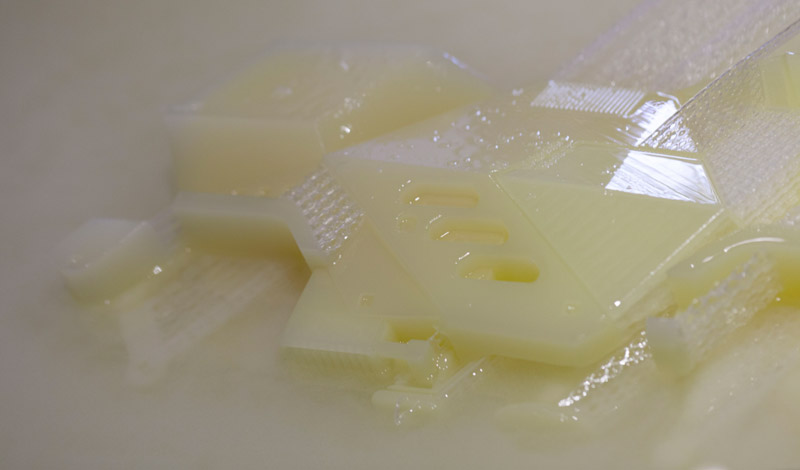

Material: photosensitive resin

Production process:

3D printing

Production cycle: 7 days

Recommended models: SLA600

Project requirements: According to the renderings and 3D model data provided by the customer, select the appropriate production process, the surface is finely processed and delivered on time.

Design concept:

In 2014, China has become the country with the longest highway mileage in the world. The development and convenience of highways have also brought more traffic accidents to the lives of the people. Among them, highway safety maintenance has become the first barrier to protect drivers and passengers, but its increasing maintenance costs are innovating in the way of highway maintenance. The highway detection & emergency treatment engineering vehicle combines highway detection and emergency treatment. The modular design of the well increases the detection efficiency, reduces the maintenance cost, and kills the accidents of road safety problems in the germination stage.

Processing challenges and solutions:

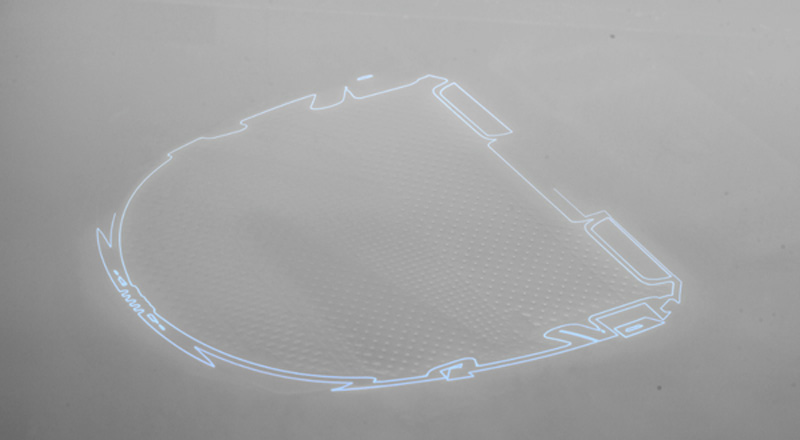

1. According to the design drawings sent by the students, our Prophase analysts selected Vistar's original high-precision, high-efficiency light-curing SLA600 for

vowin.cn' target='_blank'>

rapid prototyping. Compared with traditional manual models,

3D printing technology can express diverse and complex spatial forms and unique shapes. It can copy the students' imagination design 1:1, help students to better display their works, and

3D printing is greatly integrated. It saves material and labor costs, shortens production cycle, and meets students' creative and personalized needs.