AtVOwin , with orders of more than 100 parts, we will consider Quick Turn Tooling, Injection Moulding for plastics and Die Casting for metals. Materials could be plastics and metals. We can make rapid tooling for various plastics with different finishing, like sand blasting, texture, painting, plating and so on, depending on our customers' requirements. We can make tool life to be 5k to 100ks or more. So if you have any projects that you would only like 100pcs or 100ks pcs parts, you are welcomed to contact us for a quote.

At Vowin Rapid, with orders of more than 100 parts, we will consider Quick Turn Tooling, Injection Moulding for plastics and Die Casting for metals. Materials could be plastics and metals. We can make rapid tooling for various plastics with different finishing, like sand blasting, texture, painting, plating and so on, depending on our customers' requirements. We can make tool life to be 5k to 100ks or more. So if you have any projects that you would only like 100pcs or 100ks pcs parts, you are welcomed to contact us for a quote.

What is rapid tooling?

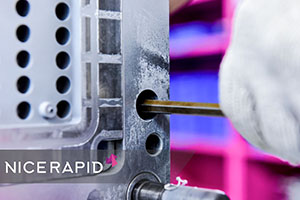

Rapid tooling is a way to simplify the mould structure for low cost & short lead-time. It's commonly used in the field of rapid injection moulding, based on the low-volume requirement. Nice Rapid manufactures its own rapid tooling in 7075 rapid aluminium (moulds can be textured) and pre-hardened P20 tool steel, to make the cavity, core and ejector plates. They are then fitted into a Master Unit Die (MUD based system) with standard tooling components, in order to produce Injection Moulding parts.

Rapid Aluminium Tooling vs Conventional Tooling?

Rapid aluminium tooling is very suitable or low-volume production prototype runs, providing a cost effective solution with shorter lead-time than traditional production tooling. For Rapid Tooling, we can typically be 30-50% cheaper than full production tooling, with a 40-60% reduction in lead-time compared to traditional moulds.

Typically, we are able to go from initial DFM design through to tooling manufacture, mould flow analysis, and initial samples in approximately 5 to 28 calendar days(depending on product complexity and tool functionality).

Nice Rapid's professional knowledge and expertise in rapid manufacturing really does cut down a lot of the time & cost of producing your prototype!

What metal material are used for rapid tooling?

We manufacture our tools from aluminium, P20, NAK80 and S136 tool steel, which can be run in a standard injection moulding machine to produce production quality parts in low-volumes. These moulds are generally serviceable for 5000 to 100,000+ units (depending on tool steel type, prototype material and tool functionality). Nice Rapid is the expert in rapid aluminium profiles and extrusions. Our extensive range of architectural and commercial products allows us to fulfil your aluminium requirements in Nice Rapid Time. No job is too big or too small… try the Nice Rapid difference!

Advantages of Rapid Tooling

Challenges of Rapid Tooling

Benefits of Rapid Injection Moulding

Bridge to Production Process

The experts in aluminium profiles and extrusions

Vowin Rapid has grown from a sole powdercoating company, today to a major distributor and finisher of an extensive range of rapid aluminium profiles and extrusions for the architectural and commercial building industry. Our head office in Zhongshan, China includes our main warehouse and powdercoating workshop. We think of it as our "beating heart" of aluminium. From here, our service flows to all corners of the world via our regional centres. It's a strange concept but aluminium is our lifeblood and it flows in our veins. We know all there is to know about aluminium shapes, colours and finishes. You can use us as a complete resource for rapid aluminium profiles and extrusions. We design and supply aluminium profiles for all your commercial and partitioning needs. Try the Nice Rapid difference and benefit from our service and experience.