Rapid Sheet me<x>tal ProtoypeRapid Sheet me<x>tal. Precision Prototype Sheet me<x>tal Rapid Sheet me<x>talSheet me<x>tal Fabricationsme<x>tal parts

Project: sheet metal parts

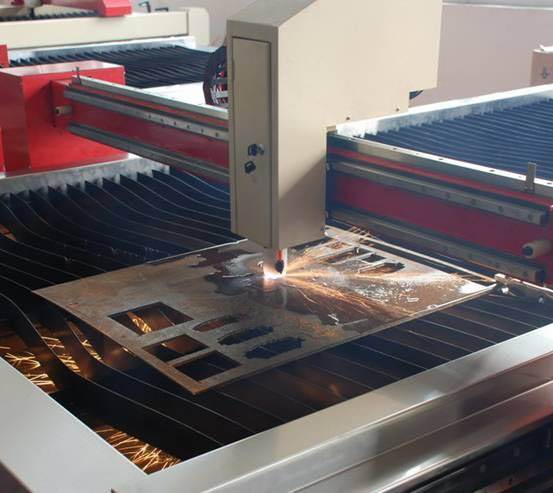

Processes: Laser cutting,Stamping,Bending,Welding,polishing

Materials: Steel

Lead Time: 8 days

Quantity: 45 Units

According to customer’s CAD files and requirements, drawing working out by engineer. Using the laser cutting machine to cut out the shape we need and forming by CNC Stamping. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining.

Afterwards Welding the parts together into a product. Then grinding and polishing for all burr and welding spot. The surface roughness can be lowered and the dirt on the surface can be purged.

At last, depending on material and customer’s requirement, We do Black electrophoresis for this products.

In general, Vowin can process the following sheet metal materials:stainless steel(303,304,316.etc),aluminum,copper,iron,galvanized sheet,CRCA.etc.

Baking finish, Powder coating, Anodizing, Electroplating(chrome plating, nickel plating, galvanized).etc We always advise our customers on the finishing options that can be used on a particular part, which is essential when your parts needs to be of high quality.

CNC Lathe, Laser Cutting,EDM, CNC Machine,Automatic Lathe, Hand Lathe Grinder,Thread rolling machine,Tapping Drilling Machine.etc.

Vowin needs clients to provide these info for quoting:Company name,contacting person name and contact info,3d/2d drawings,materials and surface treatment requirements.

Vowin promise to quote for clients within 4-24 hours after receipt of the necessary info.