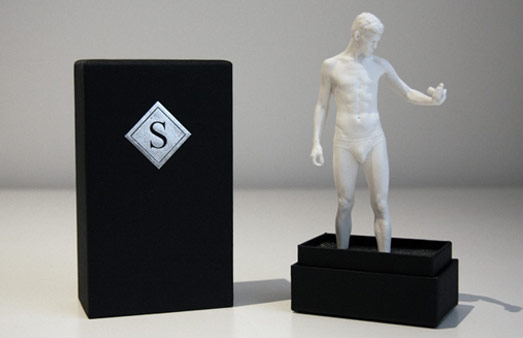

SLA is the most accurate and versatile rapid prototyping technology. SLA prototypes are constructed from a liquid photopolymer that is selectively cured using an ultraviolet laser. Due to the accuracy of this processreproduce fine details, SLA models are perfect for use as concept models, form-and-fit studies, functional testing, and as master patterns for a variety of molding techniques.