When high precision turned parts are machined with round holes, the accuracy of the round holes is often high. When the finish is bright, the boring tool is used for boring. However, many tool path parameters are not perfect. The boring tool is easily pulled back to the inner hole. Scratching a scratch is very unattractive and affects the assembly. For example, it is obviously a waste of time to return slowly in synchronous operation, which makes many peers have a big headache.

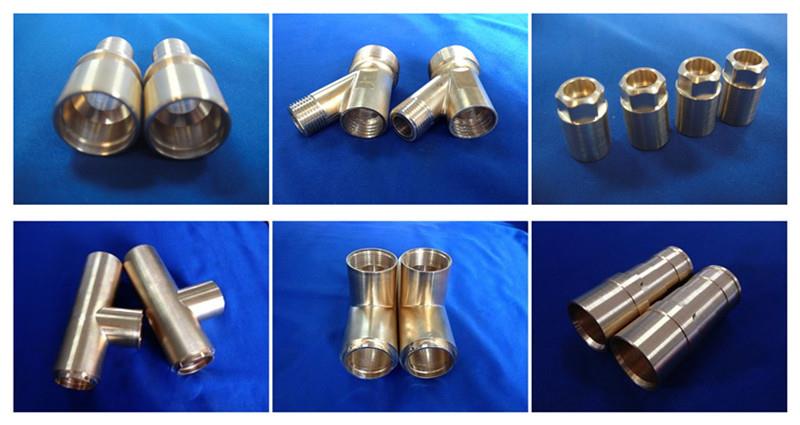

Molto has never had such scratches, no matter how big or deep the inner hole is, whether it is aluminum alloy, stainless steel, alloy steel and other hardware CNC precision parts processing, we can accurately and accurately extract high precision and high The inner hole of the brightness, this only needs to set the following parameters which can be solved.

Use the fine hole G76 to confirm that it is a single-edged boring tool. After the boring is completed, the spindle stops, the spindle is positioned, the Q value is retracted, and the boring tool is lifted, there will be no scratches on the inner wall;

The basic format is as follows, G76 X_ Y_ Z_ R Q0.1

Molto has been engaged in CNC precision parts processing for 4 years. We are constantly researching various precise and fast processing methods to help customers save cost and time.