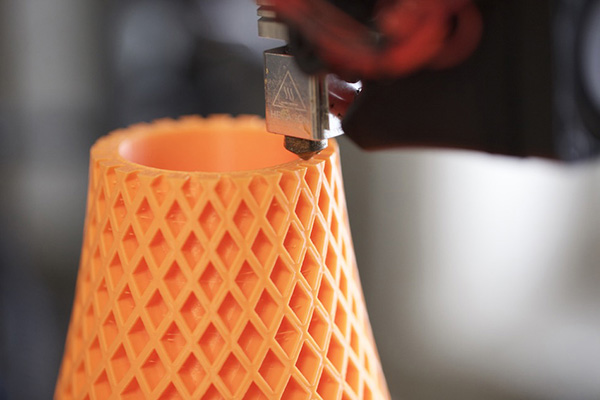

There are new additive manufacturing techniques being developed all the time. Some are best for consumer applications and others for industrial environments, but not all of them are suited for rapid prototyping. Let’s take a look at the top 7 methods for 3D prototyping and their strengths and weaknesses so that you can decide what might be best for your next project.