There are many types of pressure involved when making a plastic injection molded part. We’ve explained the importance of clamping pressure, so now let’s look at injection, holding and back pressure. It’s important for a product developer to understand how these forces work together and ultimately how balancing these forces affects part quality, pieces per hour and your product cost.

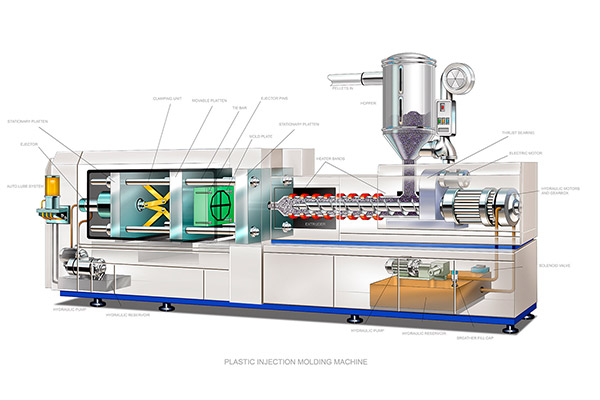

Anatomy of a standard vowin.cn/' target='_blank'>plastic injection vowin.cn/en/News/news1251.html' target='_blank'>molding machine. Image courtesy of beaudaniels.com

Injection pressure is the force applied by the reciprocating screw to push molten plastic resin into a moldcavity, up to about 95% of capacity. It’s balanced against the clamping pressure of the machine, and is calculated based on the size and shape of the part, as well as the size of the gate opening.

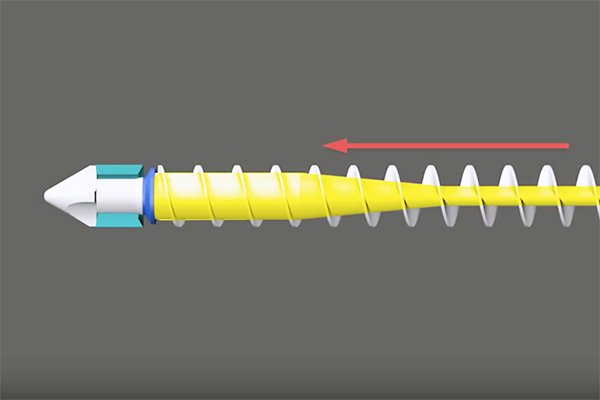

The hydraulic piston pushes the reciprocating screw forward to inject the resin

Normally product developers want to get as many parts per as they can because this will reduce labor costs, an important consideration for larger orders. But there are some limits that can’t be avoided.

First, when the mold cavity is empty, there is little resistance to flow so the cavity fills quickly and easily at the beginning of the cycle. However, when about 95% full, there will be a sudden spike in pressure that can cause flashing, or forcing the mold open prematurely. This can damage your parts as well as the machine. To avoid this, the injection pressure must be reduced in a controlled fashion, at the so-called changeover point. At this stage, the cycle switches over to holding pressure.

Holding, or packing, pressure is necessary for filling the last 5% or so of a mold tool cavity. This pressure is decreased from the initial injection pressure, and held for a longer time for a few important reasons.

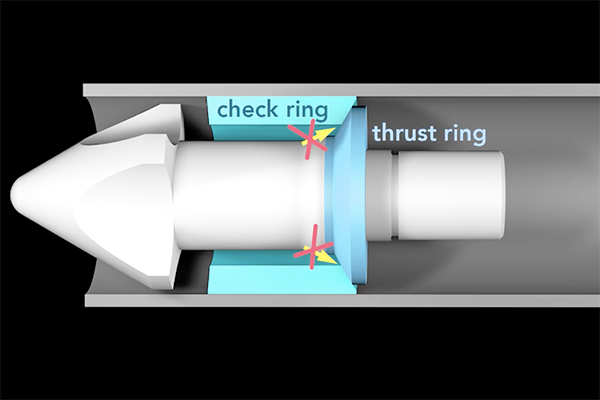

When the screw is pushed forward, the check ring prevents resin and pressure from escaping.

For one, trapped gases in the mold must be given time to escape through vents in the mold. Also, packing helps the molecules in the resin to align and achieve their highest density. Three, thin-walled sections in the part also need time to fill completely. And finally, holding pressure is essential, along with good tool design, for relieving stress in the part.

However, holding pressure needs to be balanced against another limitation. The cavity needs to be filled quickly before the gate “freezes off” and becomes blocked by solidified resin. Therefore the process engineer needs to calibrate these forces carefully within a period of time determined by the temperature and chemistry of the plastic.

Back pressure is resistance in the barrel of the injection molding machine that impedes the return of the screw to its start position. This resistance is deliberate, and is created when the operator controls a valve on the machine to restrict the rate at which hydraulic fluid is returned to the reservoir.

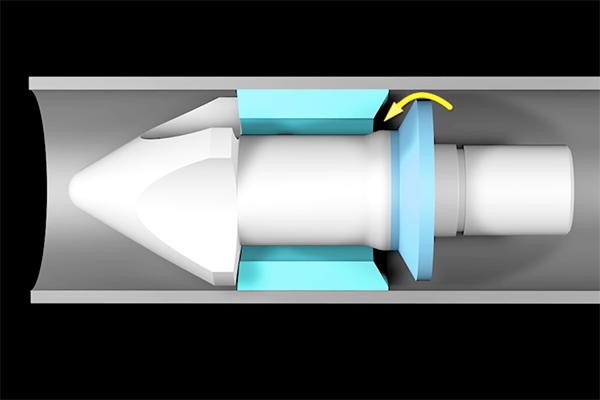

With the check ring open, fresh resin can fill the front of the screw and nozzle.

Back pressure is necessary to allow extra time for the heavy flutes on the reciprocating screw to mix the next shot of resin. The cutting action of the flutes heats the resin and maintains consistent density from one shot to the next. They also help to thoroughly mix any masterbatch coloring pigments that are in the resin.

As with the other parameters, this pressure must be controlled by the process technician so that the resin isn’t overmixed, which can degrade it due to excessive sheering.

You want to maximize the number of parts per hour in order to reduce production costs and of course to get your parts to market more quickly. But responsible process control technicians need to carefully balance multiple parameters within the machine to control quality and provide consistency from one cycle to the next.

Understanding a little more how this process works can help you communicate more effectively with your supplier, and also reinforces the importance of good mold tool design. Learn more when you upload your CAD designs for a free quotation.