Getting the best results from plastic injection molding requires that the process control engineer carefully balances several related variables when setting up the machine. One of these variables is clamping pressure.

Clamping pressure is a measurement of the force needed to hold the vowin.cn/' target='_blank'>mold closed during injection. If this pressure is not set high enough the mold will be forced open prematurely by injection pressure and will create flash on the related part.

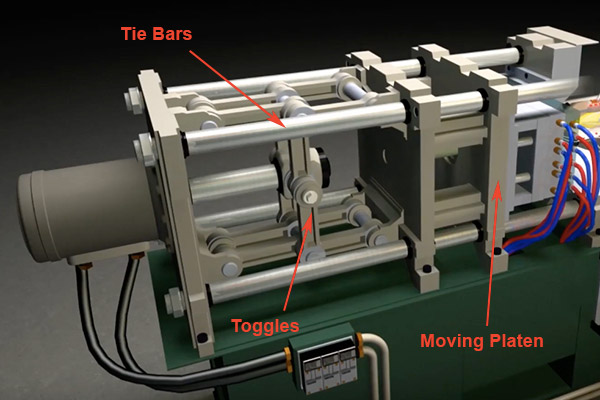

The mold opening and closing is controlled by a motor mounted at the rear of the machine. The moveable part of the mold is called the B-side, and it’s mounted on a moving plate called a platen. This platen slides back and forth on thick metal tie bars as the mold is opened and closed for each cycle.

Clamping unit of a plastic injection molding machine.

The tie bars not only guide the opening of the platen but also act as springs. When closed these bars must be preloaded with a tension higher than the injection pressure will exert. Toggles act as locking levers to make this happen.

Clamping pressure is the first variable that should be calculated by the injection molding engineer since it will determine the capacity of the machine to be used to get the best results. This is important for product developers because the choice of machine affects cycle times, parts per hour and cost.

To determine how much force the platen must hold, the process engineer will calculate using the following parameters:

These values are put into a formula that also takes into account a few other variables to yield the correct clamping force. These calculations used to be done by hand, with the aid of simple conversion charts. Now many molding programs can do them automatically.

There are other factors that the molding engineer needs to consider to set the clamping force. For example, small gates are more restrictive and therefore will require more pressure, as will thin-walled parts. And there is the question of the melt flow index.

This is a number that describes the relative viscosity of plastic resin when it’s a liquid. Typically resins that flow more easily have lower molecular weight and therefore have a higher number. Lower numbers mean the resin is thicker and more dense and will need more pressure to inject properly.

After taking all this into consideration, the smart engineer will add 20% to the total. This gives the process technician the freedom to make adjustments to the injection pressure to achieve optimal quality. i.e. where a faster injection speed is needed or a higher packing pressure to minimize sink marks.

In a production environment it makes the most sense to use a machine that can withstand the maximum clamping pressure but not much more. Machines larger than necessary represent a waste of valuable capacity that can potentially be used on bigger projects, and of course the extra power consumption and other factors are wasteful as well.

Therefore one of the first things a molding engineer should be taught is to design for the smallest machine possible. This requires understanding how to calculate the necessary tonnage as the first step.

The clamping pressure is one of the variables that will affect the size of the parts that can be made, how quickly a machine can be cycled, even how many cavities in the mold. And these factors in turn will determine the related operational costs, so it’s good for a developer to know this in advance of production.

We will be happy to discuss this with you when reviewing your project. To get your next project started simply upload your CAD file for a competitive quote.