Tell the Differences between Extrusion and Injection Molding

In the past week, we got several enquiries from new customers, they sourced the manufacturer to quote and suggest the best process for their new designs, plastic extrusion or injection

vowin.cn/en/News/news1251.html' target='_blank'>

vowin.cn/' target='_blank'>molding? Hence, we are going to talk about the differences between these two processes.

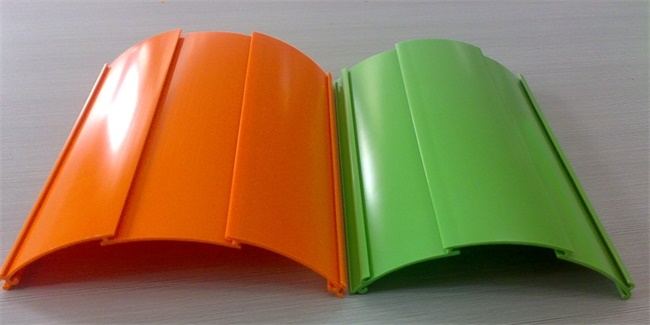

Plastic Extrusion

1. Tool: Die – a twp-dimensional die opening.

2. The melt plastic material is pressurized into the die and take the form of the die

3. Process – Continuous, the part comes out of the die in a continuous manner, shape and size.

4. Process chosen, when the third dimension is unknown, or the part needed post

machining to obtain the specifications.

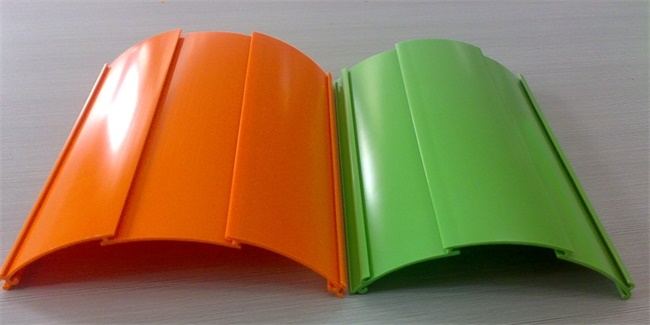

Injection Molding

1. Tool: Mold – mold structure is much complicated than extrusion mold.

2. The melt plastic material is injected into the mold.

Molded parts can be used in final assembly without post machining in most cases.

3. Process – Cyclic, clamping, injection, cooling, ejection, there are the four steps progressed every per shot.

4. Process chosen, which is used in manufacturing customized components that have clear shape, size etc.