Plastic Rapid Injection Molding is popular not only in low volume manufacturing but also in large quantities vowin.cn/en/News/news1251.html' target='_blank'>vowin.cn/' target='_blank'>molding, it is the most common way to manufacture plastic parts. Weld lines are the result of fundamental physical effects taking place inside of the mold tool cavity, they are common imperfection to be found in most plastic injected molded parts. How can we minimize them and reduce their cosmetic effects by careful product design and manufacturing process control? Let’s share our opinion and experience here:

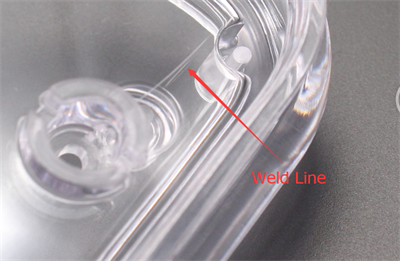

What Is A Weld Line?

We can observe a straight line or a curve radiate away from a hole, inclusion or other such part feature on the surface of a plastic injected molded part, this mark is a weld line.

How are They Formed?

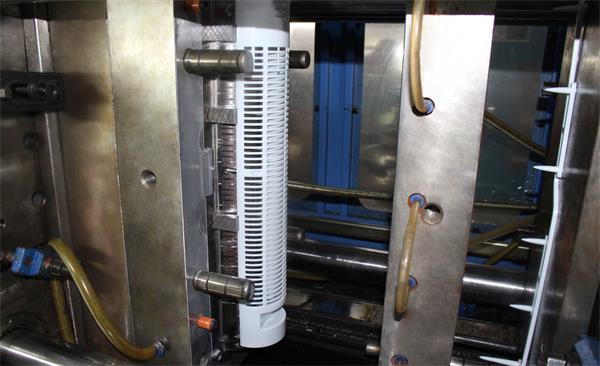

Molten plastic resin is pressuized into a mold cavity through a injection gate, it fill the entire cavity. When molten plastic contacts the wall of cavity, it cools down as the cooling channels around the wall and begin to form solid plastic shape that’s desired. However, if the molten plastic doesn’t move in one continuous unbroken path, but rather is forced to proceed around a hole or other such part feature, then the path diverges into two branches, which meet up again on the side away from the gate. These two branches are pressed together later, but they will be at unequal temperature as the plastic resin has already had time to contact the cooler tool walls and therefore has already begun to partially solidify. This solidification prevents the two branches from mixing completely and causes the characteristic weld line.

How Can We Control Weld Lines?

- Optimizing the injection parameters through combination of adjusting the molding temperature,varying the gate pressure, and increasing the dwell time. Meanwhile, Using more advanced cooling method such as cyclic cooling or conformal cooling

- Analysis the gate location, select a best injection point for reducing weld lines expose on cosmetic surfaces.

How Can We Design for Weld Lines?

Weld lines can be partially hidden by masking through intergrating fins, lines, raised or recessed lettering. Also, applying the heavy texture and light part color can partly reduce the visibility of weld lines. Please bear in mind that the weld line represent an area of comparative weakness, part failures usually happen at this location under mechanical stress. A careful designer may want to therefore add reinforcements at these critical areas.