Robots are highly complex and science-driven machines that can substitute human labor or carry out jobs we are not even capable of completing. Over the years, a lot of different robot systems have been produced to help loading, surveying and controlling a lot of industrial areas. Robot developers must pick up the pace if they want to be competitive in the market. That's why rapid robot prototyping is an obligatory area that a good designer must know well to succeed. Here are some common robot prototyping mistakes that newbies make. And some advice to avoid them.

Designers are perfectionists and they strive to make their invention both functional and pleasing to the eye. They often forget themselves and do the same with vowin.cn/' target='_blank'>rapid prototypes. They design all the complex detailed surfaces of the robotic casing and the prototype manufacturer scratches their had and quotes that he would require half a year to achieve the needed level of detalisation and vowin.cn/en/News/news1251.html' target='_blank'>machining the parts from all the durable lightweight composites the designer mentioned.

Rapid prototypes must be simplified to the maximum. If I were to compare, I'd say the final design is a spear, while a rapid prototype is just a stick. No need to waste valuable time making all the aesthetic surfaces when you can pick a block of plastic or wood the same weight and size, mount the electronics and check whether the thing moves as it is supposed to, even if for just a few runs.

Modern robots often have a multitude of functions and their final design is very complex to fit all the features into the case. Some designers think it necessary to put all the functions of the final product into the prototype and as a result, they end up wasting valuable weeks and even months adding this and that, fixing this area and upgrading this feature. All this time the prototype sits in the manufacturing facility and the development process is on hold while the designer spends tons of time chasing the perfect prototype.

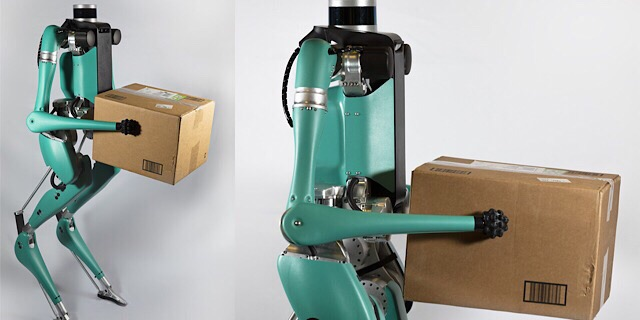

Rapid prototypes of robots must not be perfect. A single rapid prototype is aimed at checking one or two features. For example, the weight a robotic hand can lift and the height it can lift it. There is no reason to mount object detection cameras and clamping mechanisms on such a prototype, you can fix the weight on the hand with screws for al the good it would do. However, once you are done with a simple rapid prototype and tested some problem you had, you can make the final design crisper and better.

Robots are very complex because they represent a mixture of complex hardware and software. A robotic hand must have strong metal fingers but it must also be able to grip with the minimum required strength so as not to damage the part. Robotic companies like to think up and patent new functional parts such as computer vision units, control systems and so on. The more original the design is the better. However, the opposite is true for a rapid prototype of the robot. The more time you spend making custom parts, the less time you carry out tests.

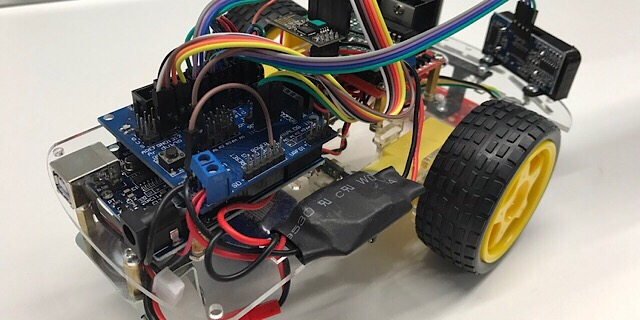

That's why it is important never to forget about standard components. You can make a lot of different robot prototype types by using simple servo engines, controllers, cameras, diodes and so on. Not only does it save you time and money making custom parts for robot prototype tools but it can potentially add to your original design or simplify it, bringing the price for the robot lower.

A lot of prototype manufacturers have a number of tools they use to develop processing sequences and what to say, they often use a default set of those tools for the majority of the jobs. For example,prototype shops use CNC machine tools widely. However, is it necessary to use CNC machining in every case or perhaps it would be easier to use a simple manual machine tool and omit the step where you need to write an NC program, upload the tools into the system and so on? The same can be said about prototype designers. Perhaps, it is enough to make a pencil sketch rather than make a whole detailed CAD model of a prototype that would be tested for a couple of days and thrown.

Modern manufacturing and developing tools are great but you have to always assess the necessity of their use. When rapid prototyping, always try to manufacture the prototype with your hands out of nothing in a minimum amount of time. A lot of robot prototypers make cardboard cases for proof-of-concept robot prototypes because there is no point in making durable elements for such a short-lived model. They spend little time on a prototype but it holds for the tests and that's it. They've wasted almost no resources while you are still milling all the robotic arm parts.

Making a great design from scratch in one iteration is an almost impossible task. You would have to finetune only the robot movement controls for months and months using trial and error method. Since the robotic industry is young, there are not enough design recommendations, which adds to the complexity. However, while the experience in this industry isn't vast, the requirements are. Especially for collaborative robots. That's why you will inevitably fail.

But that is alright. The more you fail, the more perfect your design will be and the rapid prototypes are there to help you. Just think of them as dispensable cups for the real one you are making. Rapid prototypes of robots will help your imagination see the true reaction of physical objects to different situations and the ways those situations are solved. While failing with rapid prototypes, you are bound to succeed with the real final robot.