CNC vowin.cn/en/News/news1251.html' target='_blank'>milling is one of the most impressive technological advances of this century.

Although most people are more familiar with 3D printing as a way to produce precise physical prints, CNC milling has been around for longer and is still widely used today.

From its wide range of applications in the electronics industry to its prevalent use by manufacturing companies, the technology is still rapidly growing and evolving as more and more companies are discovering its effectiveness.

So, with CNC machining expanding to new industries such as musical instrument manufacturing, it’s not surprising that the technology itself is estimated to become a 100 billion dollar industry by 2025.

Still, even though the process and uses of CNC milling are well-known to people operating in the industry, those on the outside might be much less familiar with how it can be applied or even how it works.

So, in this article, let’s dig deep into the subject of what CNC milling is, how it differs from 3D printing, who might benefit the most from the technology, and answer all of the essential questions that you might have.

CNC milling is the process of using machinery to perform precise movements and tasks, making it possible to take a digital design of an object and produce it in a physical form from raw materials.

CNC, which stands for Computer Numerical Control, allows achieving unparalleled accuracy, transforming a specific numerical code into Cartesian coordinates, ensuring that each manufactured part is produced with absolute precision, down to the smallest details, which would be practically impossible to execute by hand.

The process of milling revolves around taking material and subtracting parts until it takes the shape that is necessary, which is the opposite of 3D printing, which adds material together until it meets the requirements and specifications.

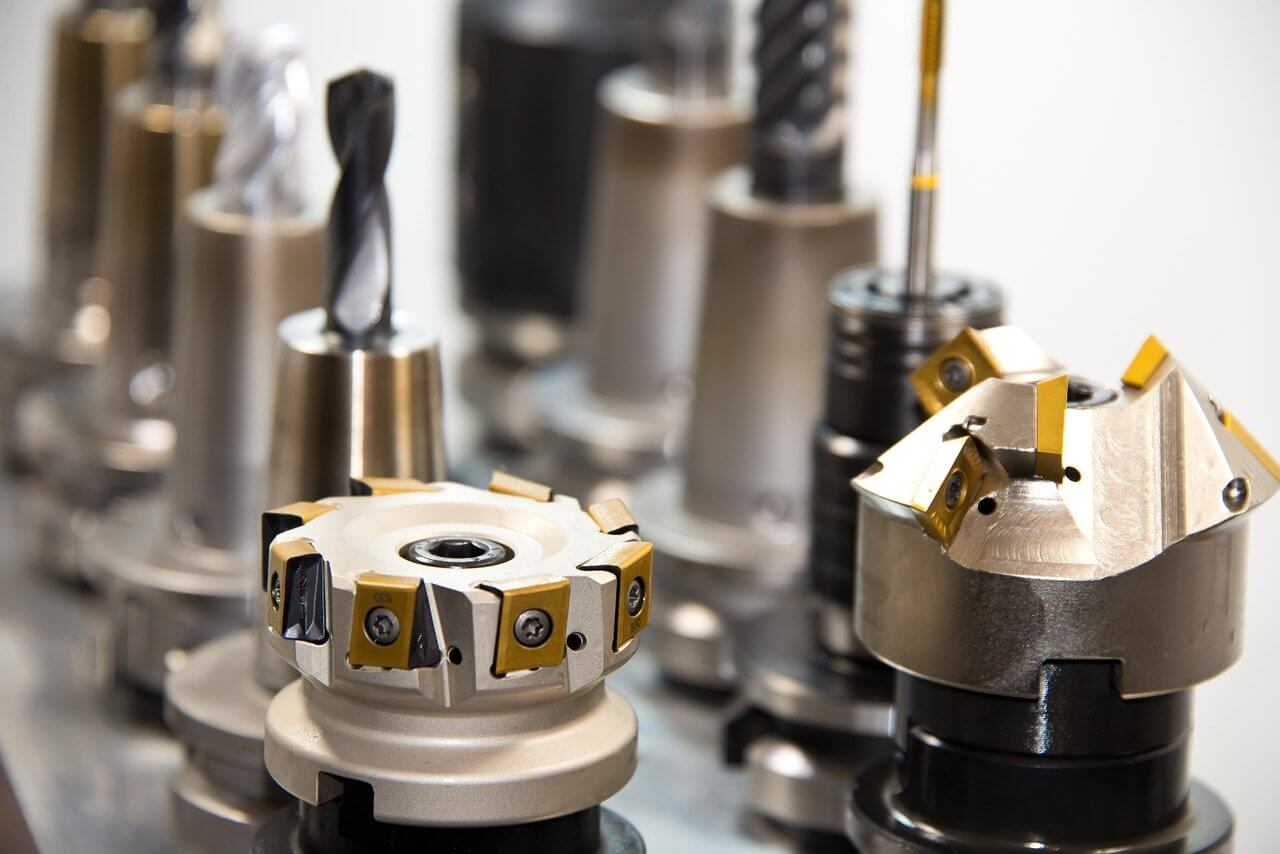

A milling machine uses a milling cutter, which shapes various metals or wood materials, employing a cylindrical tool that cuts the raw material according to the instructions.

Although this technique isn’t exclusive to the CNC approach, Computer Numerical Control provides much more precision and the ability to produce complex parts with absolute accuracy.

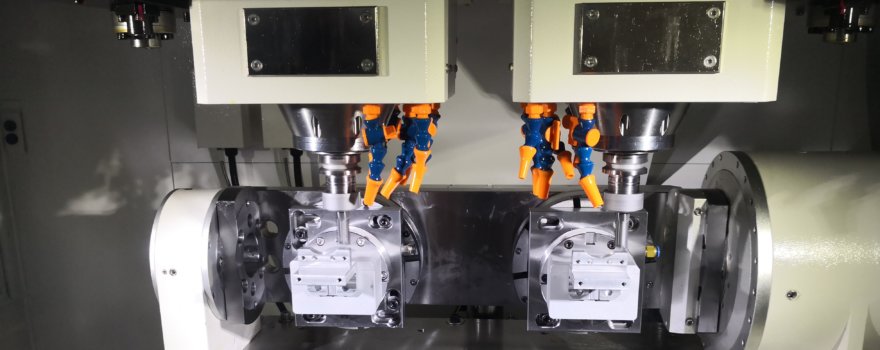

Another key feature of CNC milling is the ability to work on multiple axes, which gives it a lot of flexibility when designing unique parts.

Most CNC milling machines fall in the range between two and five axes, and the more axes are available, the more advanced the types of designs that can be created.

The CNC machines can also be horizontal or vertical, which determines how the table moves against the axis, each having their own advantages depending on the type of project that you need to get done.

Even though CNC machines are designed to handle a wide range of structures and materials, you should always carefully consider which types of milling tools you select for different tasks.

Even seemingly minor differences can sometimes produce bad results, ruining the material or even damaging the equipment. For instance, if you choose wood tools to cut steel, you will not only damage the material but will cause severe damage to the machine as well.

The good news is that if you use CNC milling services from experienced professionals, you don’t have to worry about technical details such as tool selection, as everything will be handled for you.

As mentioned in the beginning, 3D printing is one of the fastest-growing manufacturing industries in the world, projected to reach 40 billion dollars in 2024, with an annual growth rate of around 25 percent.

However, even though 3D printing has undoubtedly brought many innovations to manufacturing and helped fill niches that were previously inaccessible for companies, there’s a reason why 3D printing has not yet overtaken milling and other rapid manufacturing methods and is not projected to do so in the near future.

But since both CNC milling and 3D printing are used all around the world, let’s explore them side by side and look at what each of them can offer to companies seeking effective solutions.

The first thing we must talk about when comparing these two technologies is the fundamental difference between the process that they utilize.

As we’ve discussed in the previous section, milling is a process that subtracts materials to form a blank block to create the shapes and measurements that are necessary. Using various tools and drills, the material is shaped and cut until it matches the digital design from all angles.

Because of the wide range of tools and cutters that can be used in the milling process, the range of materials is vast as well and includes various metals, wood materials, and plastics.

Meanwhile, 3D printing takes the opposite approach, using various materials such as resins, plastic filaments, or metal powders to create parts via printing, adding them layer by layer until the whole structure is formed.

While the layers are being added, they are immediately solidified using laser or heating, producing stable, accurate, and complex parts consistently.

Using 3D printing technology provides complete freedom for creating even the most complex and unique shapes, which makes it an excellent option for those that have very specific requirements that aren’t easy to execute other methods.

The primary materials used in 3D printing are plastics. Still, more options are becoming available with advances in technology, and now metal 3D printing is becoming more accessible and more affordable as well.

In terms of scalability, CNC milling has a clear advantage, as it is much more practical when there’s a need to produce tens, hundreds, or even thousands of parts.

However, if the scale of the project is smaller, and you just need a handful of parts, 3D printing can be more affordable and allows you to create the parts very quickly. This affordability is one of the main reasons why so many different 3D printing solutions are being developed, and with time, the range and capabilities are likely to become even better.

As you can probably imagine, technology as versatile as CNC machining has a wide range of potential applications in a variety of industries.

One of the most popular ways to use CNC technology is for rapid prototyping, providing designers and engineers with a fast and reliable way of seeing how the product or part looks at various stages of development.

Whether you’re printing the initial prototype to see how it works and run tests, or want to test out a modification, CNC machining helps to quickly produce a physical copy of the design while keeping costs low.

What’s more, because of the versatility of CNC machining, it’s possible to produce tight tolerance prototypes using real materials, which helps collect accurate data and make better judgments.

If you plan on using injection molding technology, you can use CNC to create high precision copper patterns, mold cavities, or a mold base on short notice.

Production processes that used to take days can now be done within hours using five-axis milling machines that are available today, which helps speed up manufacturing processes and improve efficiency all around.

Because of the extremely high precision of CNC machines, it’s understandable why they have become widely used in the aerospace industry, where the technology plays a crucial role in producing a wide range of parts used to ensure the safety and proper function of aircraft.

Some of the parts that are produced using CNC technology include engine components, landing gear components, and fuel panels.

CNC machining also plays a vital role in the medical technology field, as it allows manufacturing parts and tools from many grades of titanium and stainless steel, which are often used in making scalpels, medical devices, as well as implants.

And with CNC technology advances that have made it more affordable and reliable, it has become more widely used for consumer products such as electronics or sporting equipment as well, especially for parts that require precision and combining metal and plastic materials.

There are countless reasons why CNC milling technology is widely regarded as one of the most reliable ways to produce parts from various materials.

Let’s look at some of the most significant advantages of this technology below.

The accuracy and precision with which CNC milling can operate are second to none in the entire world, which is why it is used in fields like aerospace and medicine that need each detail to be executed without even the slightest error.

Using a digital template and autonomous machining that CNC milling is based on, human error is eliminated from the manufacturing process, and the accuracy that is produced is as near perfection as is possible today.

Because the CNC milling machines can run practically on autopilot and don’t require much human involvement in the process, they can run without stopping for days, producing parts consistently and with the same precision.

The only time that CNC machines need to be stopped is when they require regular maintenance or if there is an accident.

The automated process that CNC milling is based on also means that fewer people are required to monitor and run it, which results in not only increased efficiency but in reduced production costs as well.

A few skilled specialists are all that’s needed to oversee the entire process, which means better cost-effectiveness for the end client.

Because of the advanced automation software and design software, CNC milling machines can outperform the most skilled technicians operating manual machines, even if the manufacturing process itself is similar.

This means not only better consistency and the elimination of human error but also the ability to produce designs that are much more complex, with varying sizes, shapes, and even textures.

Since the process behind CNC milling is mostly automated, it produces remarkable consistency, even if personnel managing the tools changes.

Once a master file of the design is created, it can be used to create an unlimited number of copies that will all be of the same quality and without any deviations. Each part will be a perfect match to the previous version, which is very hard to achieve even for the most skilled manual operators.

CNC milling can be incredibly useful for a wide variety of projects. Still, to take advantage of the benefits listed above, you must take the time to find a reliable company to work with.

There’s actually a wide range of CNC machining services offered by companies from all over the world, so you need to have at least a basic understanding of what you need before reaching out to potential candidates.

For one thing, you should have at least some ideas about what types of parts you want to be manufactured or what kinds of tools you would need. If you don’t, you’ll have a harder time narrowing down the list of companies that would be able to provide you with the necessary CNC milling services.

Alternatively, you could reach out to a reputable company that has extensive experience and offers a range of services, as they could help consult you to determine the best course of action in your situation.

Since the technology and expertise required in CNC milling projects is high, it’s imperative to seek out companies with the necessary experience, as well as a solid reputation.

Go through the testimonials and reviews from previous clients and look at what types of experiences they had with the company, as well as what problems they were able to solve.

Once you have narrowed down the list of choices to around five companies, reach out to them and ask questions about their approach, their suggestions for your project, the price for executing it, and anything else that you think could be relevant.

Quite a few companies offer CNC milling services, but while finding a reasonable price is important, it must not come at the cost of inferior quality.