The electronics industry is one of the largest and most powerful industries in the world, and many of its products — from professional high-tech equipment to consumer electronics — are made with CNC machined parts.

Machined components for the electronics industry include both plastic and metal parts, and technologies used to produce them include CNC vowin.cn/en/News/news1251.html' target='_blank'>milling machines and CNC turning machines. Precision CNC vowin.cn/en/News/news1251.html' target='_blank'>machining allows for the production of fine-detailed components such as circuit boards, and several machining technologies enable the mass production of components at scale.

This article looks at how the electronics industry uses CNC machining — and how 3ERP can help you successfully bring your electronics prototyping and manufacturing projects to completion.

Electronics is a huge global industry that encompasses several distinct sectors. The largest of these is business-to-business e-commerce, which includes the ubiquitous payment and telecommunications technology used for transactions between businesses. This sector alone accounted for $29 trillion in sales in 2017.

Other significant sectors of the electronics industry include the tech industry, consumer electronics, the semiconductor industry and power electronics.

Across these sectors of the electronics industry, some of the most widely manufactured components include transistors, capacitors, semiconductors, diodes and circuit chips. Popular products, which consist of many electronic components, include computers, televisions, radios and smartphones.

The accuracy and versatility of CNC machining makes it a valuable manufacturing technology for the electronics industry. CNC machines are capable of processing conductive and non-conductive metals, as well as a wide range of plastics.

One of the biggest advantages of the technology is speed. CNC machining can be used to produce electronic components within a short timeframe, since there is no tooling stage before production, and the technology does not suffer from the quality limitations associated with additive manufacturing. Designs can also be quickly iterated and amended using CAD software, with little manual operation required once toolpaths have been defined by the computer and/or machinist.

Many electronics manufacturers require tight tolerances for intricate internal components, and CNC machining is often the most suitable technology for meeting such requirements.

Consumer electronics

Consumer electronicsThe Apple MacBook and its various models (MacBook Pro, MacBook Air) is one of the most recognizable consumer electronics products in the world, and its durable aluminum body is made using CNC milling technology.

The body of an Apple MacBook is made from a single extruded piece of aluminum, with keyboard holes and other contours then CNC milled out of the block of metal. When the company first started using this process in the late 2000s, then-CEO Steve Jobs said: “Apple has invented a whole new way of building notebooks from a single block of aluminum.”

Unfortunately for its competitors, Apple remains the only company capable of CNC machining laptops on such a scale. The computing giant operates a reported 10,000 CNC machines, which is beyond the financial reach of other businesses in the field. Other companies can, however, use CNC machines to manufacture electronics bodies and enclosures on a smaller scale.

The manufacture of semiconductors is arguably the backbone of the electronics industry, with the MOSFET (metal-oxide-semiconductor field-effect transistor, or MOS transistor) being the most widely manufactured device in human history.

Since precision CNC machining equipment is capable of processing semiconductor materials like silicon and aluminum nitride, it is frequently used by semiconductor manufacturers. Machinable semiconductor components include wafer chucks, gas distribution plates, wafer carriers, solder pad stencils and flex circuit stiffeners.

These parts generally need to be made to tight tolerances, since semiconductors are often scaled down to very small sizes to fit into electronic devices.

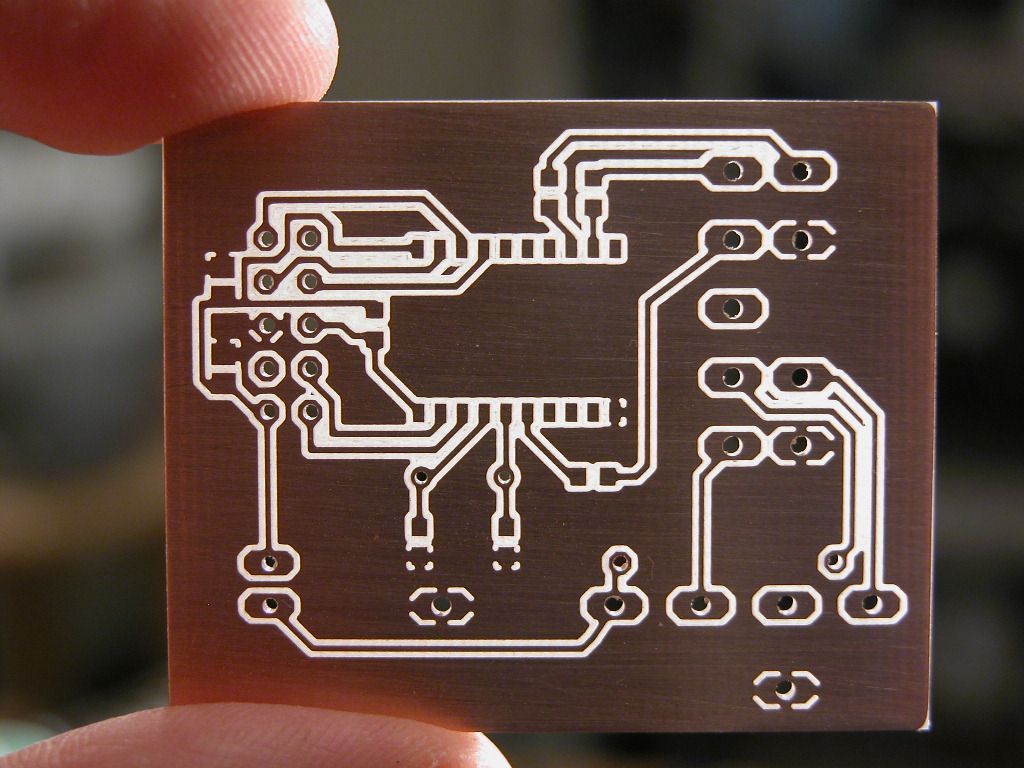

Printed circuit boards (PCBs) are used in most electronic devices, and serve to link up the various parts of the device, with wiring soldered to the appropriate area of the PCB. They consist of conductive tracks — usually made from copper — and a non-conductive base layer underneath.

Most PCBs are made using a process of chemical etching, in which the PCB designer can cover up parts of the copper before submerging the board in an etching solution such as ferric chloride. The solution removes the uncovered areas of copper, leaving behind the desired network of channels.

For small-scale projects, CNC machining can function as a suitable alternative to etching, especially in environments where etching solutions may be considered dangerous. Machined boards, where sections of the copper are simply milled away, can be designed using CAD/CAM software and fabricated using a standard CNC milling machine.

Heat sinks are widely used electronic devices that transfer heat from an electronic part to a liquid coolant or into the air. Used in devices like computers, heat sinks serve to cool down critical components to maintain proper function.

Using machinable metals such as aluminum or copper, it is possible to create heat sinks using CNC machining technology. Precision CNC machines are capable of fabricating even very small heat sinks, and can create the devices in various configurations depending on requirements.

Machining is often favored for small production runs of heat sinks, and can be used to make very complex contours, cutouts and other features. Machined heat sinks also offer high thermal conductivity.

Vowin has worked with many customers in the electronics industry, completing prototypes and low-volume production runs for a wide range of specialist components.

We specialize in precision CNC machining, and can provide high-quality finishing procedures for all parts.

Request a quote today to get your project started.