Any workshop worth their salt is always looking forward to learning about new manufacturing technology that can help them increase their productivity. New technology in the field frequently appears since this is probably one of the most competitive markets worldwide. The latest developments, however, can take a lot of time to master appropriately, and not every team has the patience for it. Many workshops stick to their known guns for a long time, and quite frankly, that could be a pretty terrible mistake on their end.

CNC vowin.cn/en/News/news1251.html' target='_blank'>machining is probably one of the most competitive fields in the manufacturing industry, and many workshops around the world handle internal holes following hole-depth-to-diameter using 8X without regard for tooling. By rights, you should get a 2-inch deep hole, but it doesn’t work that way if you haven’t made a proper study of the materials you are working with. This only brings additional expenses for the workshop that cannot be placed in the client. At the same time, that also decreases the revenue for a manufacturing task since the workshop is losing materials on trial tests.

Fixations With the Past – The Trials of Modern Manufacturing

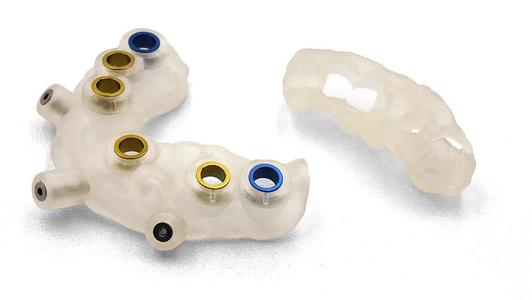

The thinking behind many modern workshops is that true and tried methods are suitable since they work based on universal principles. But the current demand of many industries is calling for radical redesigns on their products and the parts they need. If the workshop can’t adapt, their clients will take their business somewhere else. Rapid tooling and 3D printing are helping many companies to catch up on this regard. New methods of injection molding tied to this technology have made it possible for many of these workshops to fulfill orders since they are now familiar with concepts such as bending radius for metals, gouging materials, and keeping bends and holes in accordance to specifications.

While it’s true that rapid tooling and 3D printing can help workshops sort out many issues, there seems to be a consensus among many people that the technology is a cheat code that allows manufacturers to get away with fulfillment without proper testing and trial. That’s is not valid. Users of this technology are already familiar with the fact that the surfaces of the finished products are not delivered following the specifications of the client, or the fact that specific dimensions are botched making the product too rigid or too fragile to work correctly. It takes years to master rapid tooling and 3D printing to handle additive manufacturing the way it should be.

Overcoming the Paradigms of Manufacturing

The challenge faced by most workshops trying to catch up with their competitors is that 3D printing and rapid tooling do not reflect their expectations at all. The manufacturing procedure is far from perfect in their eyes, but the hard fact is that it needs to be mastered to work correctly. For better or worse, the outlook of the whole industry has changed, and those who shift their effort to fulfill the needs of their clients are the ones who can keep running their workshops. As it stands right now, it seems that the whole issue can be solved with education and training. Half-measures lead to mediocre output, and that kills any business.

Once we understand the basics of rapid tooling and 3D printing, we also have to improve every other stage of the manufacturing procedures in the workshop. When something doesn’t work at prototype levels, a little tweaking won’t do; the whole designs must be revised. When the finished prototype is functional, we can go to the production cycle. When something is not working in the interim communication is essential to solve any issue. Inspection should be a norm before going to the next phase of any manufacturing project. Tolerances must be tested. As you can see, nearly all the stages of any manufacturing task need revisions.

Subtractive manufacturing worked well for many companies for a long time. As a matter of fact, it had quite the long run. Additive manufacturing has been around for a time now, and some people still cling to the past. Rapid tooling and 3D printing should be the norm of the industry right now, but the paradigms are still shifting after 20 years in the XXI century, and that’s not good. It shows resistance to change and a lack of motivation to improve. The new methods indeed require more communication and revisions, but they also guarantee better products and better output. Machinists, engineers and workshop owners must be willing to embrace change if they want to succeed.