No matter which indusrty, quality is a key factor bacause everyone all like to purshase nice quality goods. Sometimes quality is even the foundation of an enterprise. So as a qualified CNC Machining supplier, what should we do to control quality? There are some tips that to help you improve your quality control.

1 Double-check orders and understand the design of products

After received the customer’s order confirmation, we need to double-check the details of this order, such as materials, quantity, post-treatment…Sometimes the order are different from the initial quote you offered, so we need to double check all detailed things.

When receiving the CAD drawings of the final products from customers, our engineers and technicians will carefully analyze the design of the products to understand the specifications and requirements of the products, so as to suggest the most cost-effective solution to process the parts, save the processing cost and achieve the maximum benefit of the processing products.

2 Check detailed requirements of drawings

Usually some detailed requirements like holes, threading, tolerance, chamfers…would be marked on 2d drawings. We need to check these information carefully before production in order to advoid second-manufacturing. This can save cost and time, as well as to keep the tolerance requirements.

3 Incoming material inspection

Good quality material can make high quality products, so incoming material inspcetion is very necessary and important. The inspection can help us to screen out inferior raw materials, while avoiding the risk of product processing, saving cost and time, is an essential step before the control of product production.

4 Inspect the first piece

When the first product is ready by CNC Machining, we will send it to the quality control department for size and appearance inspection. Only when all the indicators of the first product meet the requirements will the production department be notified to continue production. This can ensure the quality of the same batch of products in the same level to the greatest extent.

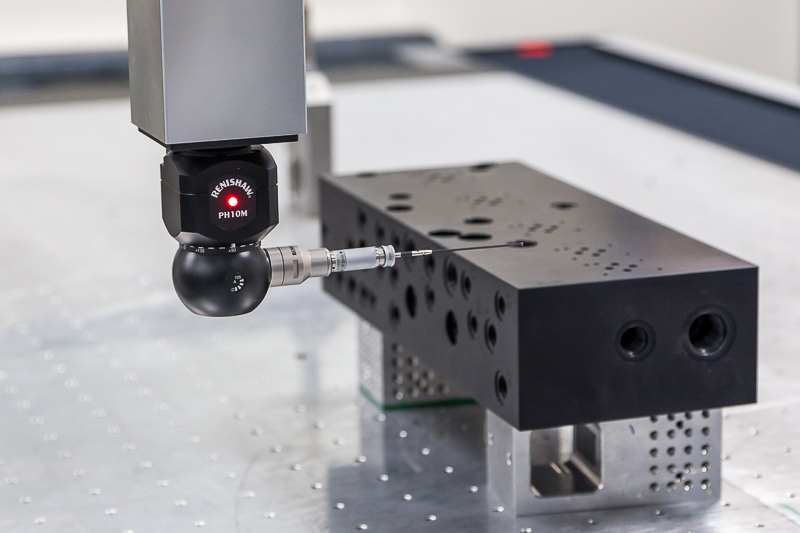

5 Provide final inspection, testing reports, and certification files

After all the products have been finished, we will do final inspection and provide an inspection report or teting report to customers. Generally speaking, the products absolutely beyond the tolerance range found in the inspection will be directly sent to the production department for re-production. Sometimes, several or part of the products in a batch will slightly exceed the tolerance required by the customer. We will send the test report to customers and solicit their suggestions. Customers can better judge whether the product is available after comparing the test report.

The above is in the CNC processing how to control the quality of some tips, these tips in the processing of products is also very helpful. Any processing, all need to follow a certain process to make. If you are looking for a high-quality prototype and custom mechanical parts supplier, please feel free to contact us via crystal@vowin.cn