Small batch processing including CNC processing and Vacuum casting two ways, CNC processing can make plastic, can also make metal. Vacuum casting is a kind of pro prototype processing method, suitable for making small batch cnc vowin.cn/en/News/news1251.html' target='_blank'>machining soft adhesive, ABS, nylon and other materials of the hand plate, Vacuum casting production cycle is short, low cost, but its production accuracy is only ±0.2mm or so, if the model precision requirements are very strict, try not to choose this way to do.

CNC processing is more commonly used prototype processing, processing accuracy than other processing methods to high, the processing of a wide range of materials, plastic and metal materials can be processed, there are high requirements for the precision of the proposed use of CNC machining.

The main advantage of small batch cnc machining is low cost and short production cycle. For example, CNC processing needs a few hundred dollars to do the prototype, using Vacuum casting to do, only a few dollars can be done, dozens of prototype 3 or 4 days can be done. Effectively reduced the enterprise new product design and development time and cost.

1: the original version should be made before the production of vacuum casting. The original version is usually done by small batch cnc machining or 3D printing. After the original version is finished, the manual department can be polished. The materials of silicone mold are: ABS, PP, PC, POM, PA, soft adhesive and so on.

2: Vacuum casting: mainly used for small batch prototype, short cycle, low cost, but the performance and precision of prototypes is not as good as CNC machining, under normal circumstances, the service life of silica gel mold is about 10-20 times.

The probability of making mistakes is small, as long as there is no problem with the prototype, there will be no problem with the product.

But the disadvantage of small batch cnc machining is to make the finished product, will be affected by hot expansion and cold shrinkage, resulting in the size will shrink, these factors should be considered, otherwise the prototype is not qualified. Small batch prototype model processing compared to CNC processing, in terms of accuracy cannot be compared, so the use of the above two processing methods have their advantages.

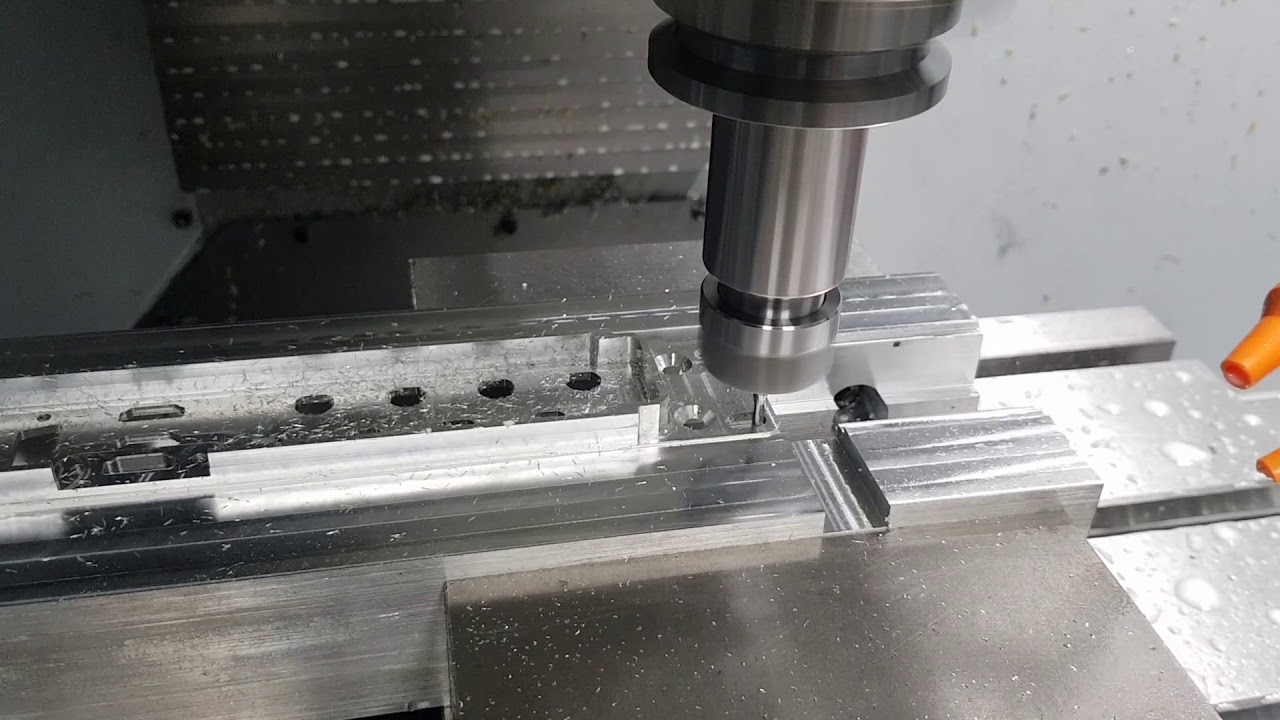

Nice Rapid hasmore than 20 years experience in CNC machining. Customers from a wide range of industries, primarily in aerospace and defense. Turn to us for both large and small batch cnc machining services. A low volume approach toCNC machining is very different from the regular volume production strategies that many precision companies employ. CNC machining Workshop Optimizing a component for production, whilst ultimately very important, does not apply when producing a single part or small batchCNC machining. We usually take quantity from 1-3,000 for small batchCNC machining production. We accommodate other materials of your choice too. With your CNC designs, we can create prototypes, products in small batch cnc machining, and low-volume production of finished parts.

When you require a low cost per part for a custom small batch cnc machining part, it’s the right decision to opt for custom machining. Few pieces of complex components using this manufacturing process has a lower price than other manufacturing processes. An example is when producing low quantity plastic parts. CNC machinists are happy to manufacture a few hundred parts rather than injection mold companies to make tooling first before starting the process.

Request a quote today, or contact Nice Rapid to learn more about our large and small batch cnc machining services.