Prototype Plastic Parts is a professional manufacturing technique used to produce a high quality physical model. It has three-dimensional design. The prototype is useful for design improvement.

Moreover, it can be used as a stepping stone for comprehensive production tests. With vowin.cn' target='_blank'>rapid prototyping, you can manufacture parts or products to test for part fit and function.

According to the result of the analysis, the product can be further adjusted. You can do it before finally entering the market.

Prototype Plastic Parts can help save time and cost-effectively. Many of customers need to manufacture the physical part immediately. It is to confirm the design or the possibility of the part.

Nowadays, various types of rapid prototyping processes are available. You can choose the process that best suits your needs. With only 30 years of development, the name means rapid prototyping technology has already been widely used in many regions.

Meanwhile, rapid prototyping services are still growing at top speed.

Prototyping is a complex, demanding and time-consuming job. As a rule, the execution of such tasks is given to a third-party contractor with extensive experience and a high level of professionalism.

Prototyping is a set of industrial techniques aimed at the physical realization of an object.

Prototype Parts has three phases:

At the end, it can then go on to the actual production of the piece.

The prototype, therefore, is the original model. It is normally built in an artisanal. So we can carry remaining process with the Prototype Parts development.

Prototype or Prototype Mold: which option is best for you?

There is progress at the server level for Prototype Parts. what you choose really depends on what you expect to achieve with the real part. For example:

The most common way to make it as rapid prototyping, these options is:

Prototype Plastic Parts are always developed for a specific purpose. It can be a matter of trying out a technical idea. Moreover, it can be for checking the customer’s requirement.

This focus on individual aspects helps to keep the costs of producing a plastic prototype low. A plastic prototype with a focus on design will not need a technical interior.

Therefore, a technical prototype does not have to look aesthetic. Similarly, it is often a tangle of cables and circuit boards.

Thus, the role of a prototype is to provide answers to design questions that arise during development. Unfortunately, not all questions can be answered in theory.

Most potential customers’ ability to abstract is limited. In addition, it is why at some point in development people have to give feedback on a real plastic prototype.

Prototype Plastic Parts are also suitable for communication early in the development phase. Investors or potential customers at trade fairs show great interest in plastic prototype. It is perceived more positively than if he can only talk about his ideas in the abstract.

But why not build the entire end product and get the appropriate feedback? Why the detour via the plastic prototype?

There are multiple reasons for this:

You can already verify individual aspects with a plastic prototype. No matter if others are still unclear at this point.

are an indispensable part of modern product development. Moreover, they should not be ignored by any producer.

There are different techniques with which plastic prototypes can be produced. 3D printing, in particular, has given simple options for testing product ideas quickly. Furthermore, it requires little effort using prototypes.

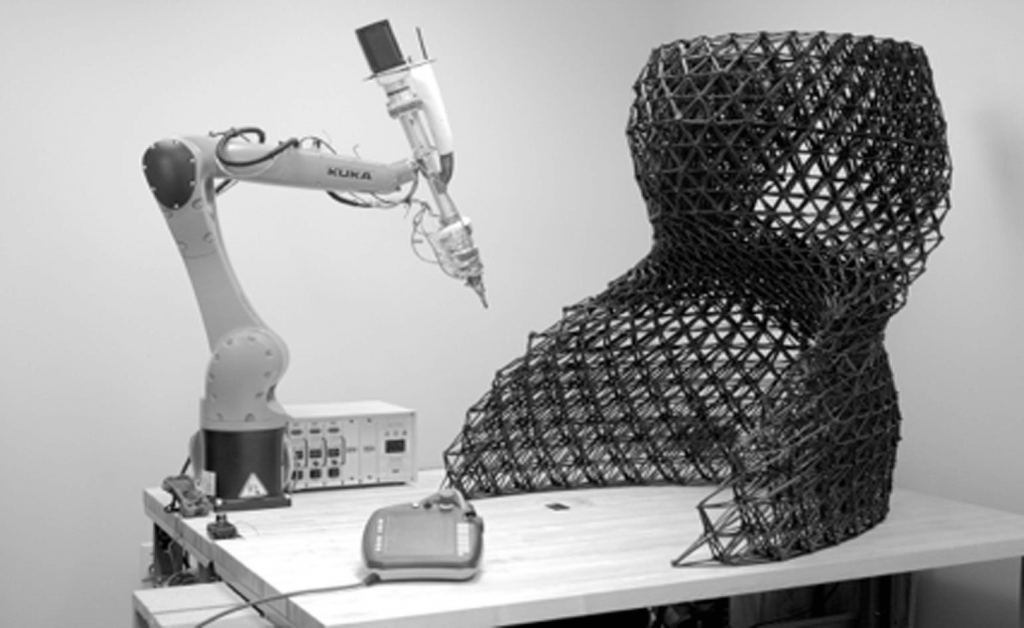

In 3D printing, the prototype Plastic Parts is built up layer by layer using liquid plastic and a nozzle. In the meantime, even complex objects are possible. The data for controlling the 3D printer are processed on a computer and made available to the 3D printer.

Another technique that has been tried and tested for years is injection molding. This is more expensive. Because molded parts have to be produced. In the meantime, however, the technology is so mature that even small quantities are profitable.

3D printing is particularly suitable for individual Prototype Plastic Parts. Similarly, injection molding is useful for the production of medium quantities.

-Reduction of time and costs.

Unfortunately there is the belief that prototyping cannot be used with a very strict and exhaustive deadline. Fortunately, thanks to 3D printing, it was possible to change those who thought in this way.

Plastic Parts through the 3D printer does not slow down the study time of the project. On the contrary, it turned out to be one of the fastest and cheapest prototyping methods.

Thanks to this, the customer has the possibility to anticipate expensive costs. But he can also identify errors or potential disasters in time.

A well-built prototype Parts guarantees quality and durability of the object over time.

Many customers want to be involved even in the most difficult and complicated system of Plastic Parts. Prototyping favors teamwork. Hence, it allows the customer to be present during all phases of the project.

Thanks to prototyping, the customer can give:

The fundamental role of the prototype Plastic Parts is to avoid misunderstandings during the development process.

We support you in the development of your product and the development of Prototype Plastic. It is always important to us that the plastic prototype is developed according to your individual needs.

It is best to consult us early in your product development phase. This enables us to advise you when the best time for the first plastic prototype is.