CNC vowin.cn/en/News/news1251.html' target='_blank'>machining is a technology that is widely used in the manufacturing of medical instruments. It can be used to create a wide variety of parts and components with precise dimensions and shapes. CNC vowin.cn/en/News/news1251.html' target='_blank'>machining is a fast and efficient way to produce high-quality parts and components.

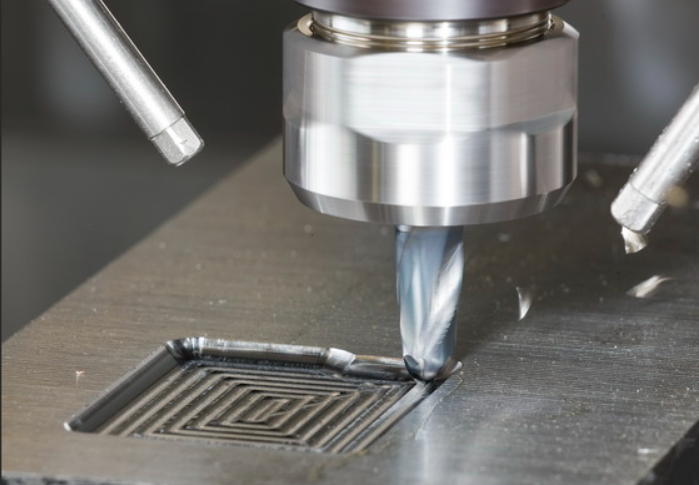

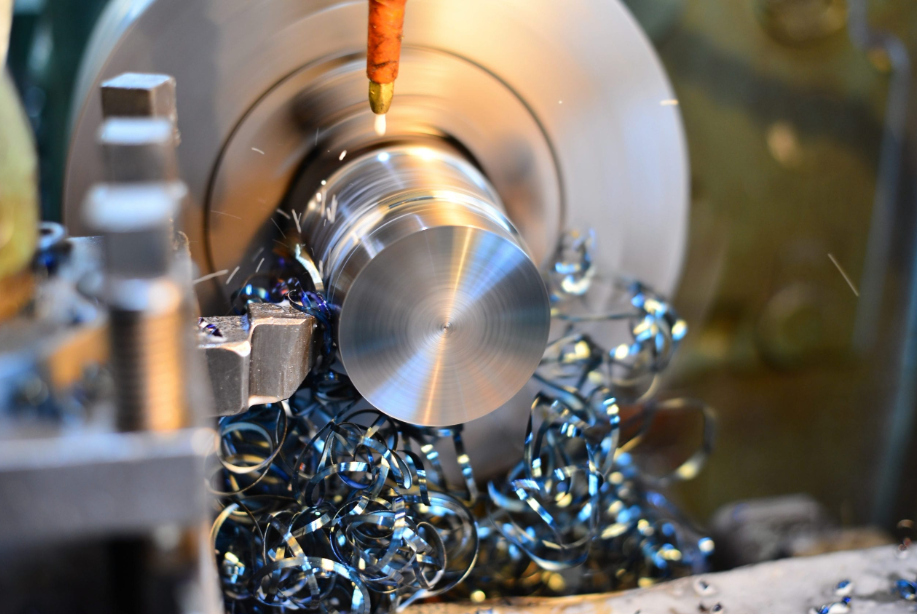

CNC machining in medical instrument manufacturing typically involves the use of computer numerical control (CNC) machines. CNC machines are computer-controlled tools that can create highly precise parts and components.

CNC machines are often used to create complex shapes and contours that would be difficult or impossible to create with traditional machining methods. CNC machining can be used to create a variety of different parts and components for medical instruments.

CNC machined parts can be used for everything from medical devices and implants to surgical instruments. CNC machining is an essential part of the manufacturing process for many medical instruments.

Benefits Of Using CNC Machining In Medical Instrument Manufacturing!

There are many benefits to using CNC machining in medical instrument manufacturing. CNC machining can produce parts and components with very tight tolerances.

This means that parts will fit together more precisely, which is essential for medical instruments. CNC machining can also create complex shapes and contours that would be difficult or impossible to create with traditional machining methods.

CNC machining is also very efficient, which can save time and money in the manufacturing process.

CNC machines can operate 24 hours a day, 7 days a week, and can produce large quantities of parts very quickly. CNC machined parts also have a very smooth surface finish, which is important for medical instruments that need to be sterilized.

Overall, CNC machining is an excellent choice for medical instrument manufacturing. It provides many benefits that can save time and money, while still producing high-quality parts.

CNC machining in medical instrument manufacturing can provide many benefits including:

- Tighter tolerances

- More precise fits

- Smooth finishes

- Consistent quality

Each of these benefits can be extremely important in the production of high-quality medical instruments. In many cases, CNC machining is the only way to achieve the level of precision and accuracy required.

- Tighter Tolerances: CNC machining can hold very tight tolerances, which is essential for many medical instruments. In some cases, the tolerance may need to be as low as 0.001” (0.0254 mm). This means that CNC machined parts will fit together perfectly, without any gaps or looseness.

- More Precise Fits: CNC machining can create parts with very precise fits. This is important for medical instruments that need to mate with other parts or components precisely. For example, CNC machined connectors and tubing can be made to fit together perfectly, without any leaks.

- Smooth Finishes: CNC machining can create smooth finishes on parts. This is important for medical instruments that need to have a smooth surface, such as catheters or stents. A smooth finish is also important for parts that will come into contact with human tissue.

- Consistent Quality: CNC machining can produce parts that are identical to each other. This is important for medical instruments that need to be interchangeable, such as implants. It’s also important for instruments that need to be sterilized, as any imperfections could provide a place for bacteria to grow.

How Does CNC Machining Work And What Are The Different Types Of Machines Available On The Market Today?

CNC machining is a process where computer numeric controlled tools are used to create parts from a variety of materials. The first CNC machines were created in the 1940s and were used for industrial applications.

Today, CNC machines are used in a variety of industries, including medical instrument manufacturing. There are three main types of CNC machines available on the market today: