Studies have found that the CNC vowin.cn/en/News/news1251.html' target='_blank'>machining market will exceed 100.9 billion worldwide by the end of 2025. That is just four years away.

Many industries have started using this machining to bring a change in their production. If you see many people around you who have chosen CNC machining over other types, it’s time for you to choose the same. But what is CNC machining?

What Is CNC Machining And Its Process?

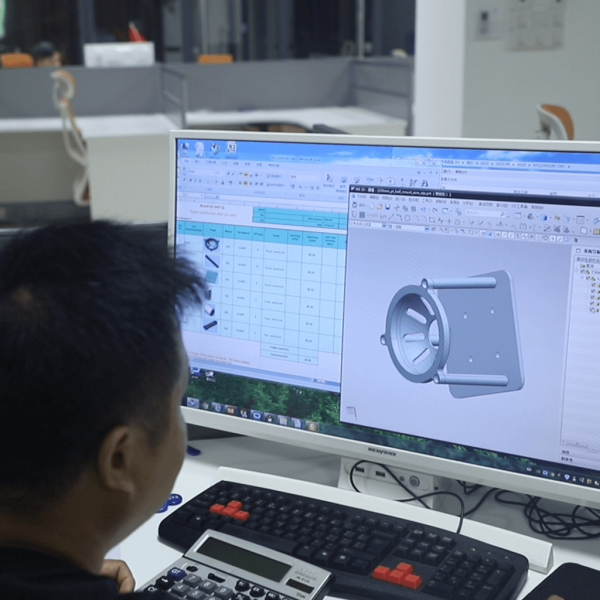

CNC machining model

It creates your final design by performing many tasks. Customers ask for a special shape, and we make it possible through CNC machining.

It is now used in medical, aerospace, and defense. It has changed the way we used to look at the world. CNC machining makes everything accurate and precise.

It performs the same functions such as metal cutting, grinding, and milling as traditional machining. One difference is that it is done through a computer rather than a machinist.

Unique software called the ‘CAM’ is used in this machining.

Through the CAD model, instructions are given. These instructions are changed into G-codes, and these G-codes instruct the machine on how to work.

It uses raw material and changes it to its final form by removing materials. For its final shape, it drills holes and bore pathways into the material used.

Mostly the work is done like a robot. As you put in the desired information, it starts working on the end product, and you get it quickly.

Types

CNC milling

Technological developments have changed the face of the earth. After analog computers, now digital computers are used.

This has led to the rise of CNC machining. Some CNC processes are hole-punching, ultrasonic welding, and laser cutting. Some of the types of CNC machining are discussed below.

CNC Mills

It is run by prompts made by programs. These prompts are letter or number-based and guide pieces along with a great distance—we either program using G-codes or some other language developed by our experts.

There are three axes called the 3-axis, 4-axis, and 5-axis. Some new mills use all three of them. 3-axis and 4-axis are used when simple shapes are required by the customer.

If the customer needs more complex shapes, then 5-axis is used. 5-axis is more efficient. Our specially designed milling machines can cut through any solid material.

Our tools are specialized to make the parts into their desired shapes and sizes. These tools may include cutters, fluted mills, face mills, and

CNC Lathing

ball end mills.

A surface finish is required to change the appearance, hardness, rough surface, and chemical resistance. It is after this that we start inspecting the end product before shipping it to our valued customers.

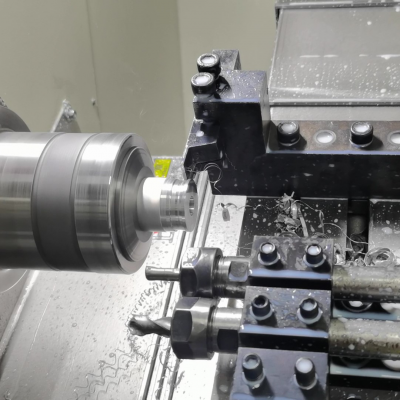

Lathes

Different tools cut the material in a circular direction. These cuts are made with high speed. You don’t have to worry even if your design is complex. Lathes can deliver your end product on time. It is capable of making designs that cannot be made manually. These are run by G-codes too. They consist of two-axis- X and Z.

Plasma Cutters

In plasma cutters, plasma cuts the raw material. Electrical arcs and compressed-air gas are combined to make the plasma for this machine.

This plasma is needed for the required heat and speed to cut the material. This process is for materials that are metal, but it can be applied to other materials too.

Electric Discharge Machines

EDM

Some other names of this type of machining are spark machining and die-sinking machining. This machine shapes the workpiece into different shapes using electrical sparks.

Electrodes discharge current, thus removing pieces of the workpiece. Portions are removed from the materials through spark erosion.

It becomes stronger than the dielectric. Electric fields between the electrodes become intense because the space becomes smaller.

Each electrode removes a part of the workpiece. Flushing is a process in which waste from the finished workpiece is taken away by the liquid. It is even called a wire EDM.

Water Jet Cutters

This machine is known to cut through hard materials. Some examples of hard materials are metal and granite.

They are very stubborn when machining. The pressure of water is applied to these materials. We sometimes mix sand with water so that it becomes much stronger.

Factory machine parts are usually made through this process. We use this when materials cannot bear the heat from other CNC machining processes.

People who work in the mining and aerospace industries rely on water jet cutters. They need their parts to be made through a cooler process.

If you need detailed cuts on your material, we would advise you to go for this. This type does not change the delicate properties of the material; thus we get to pay much attention to detail.

Some Of The Advantages Of Using Our Prototype Machining For Product Development Are Listed Below.

-

Accurate

Our CNC machining creates precise end products. The computer only follows the instructions given.

Its movements are controlled. It is highly accurate. We work on many projects at the same time, so accuracy is repeatable.

-

Fast

We deal with all kinds of rigid materials. You have come to the right place. It is the fastest way to make parts. We can now make your parts quickly with the new technological developments.

This includes the setup and processing time. It is by far the fastest process. The file is created in a few hours, whereas the real cutting process takes just a few minutes.

As soon as you think about a specific part, you can get it in a matter of a few hours. It will then be evaluated by the client and us.

This way, you can start your production in just a day. Approving the molds is a very long process. Injection molding is much faster, depending on the parts.

After this, the parts are measured, painted, and go through the second process.

-

Flexibility

RJC can even make a hundred parts in a matter of some hours. It is for you if you are a new developer and you are not sure how your customers will react once you launch the product.

It saves the production cost. It is for you if you do not have an inventory. Now you can get your products made on-demand.

-

Modification

Now you can change anything in your design at any time. Reach out to us, and we will help you. Once the end product is in our hands, we test them.

We evaluate the results and change the design if you’re not satisfied with the results. This technique saves your time and money.

We will never let you go into production if the parts do not work.

-

Quality

Quality always comes first when making CNC machining parts. Quality is not just limited to the raw material and the shape of the design.

It shows in the appearance and the surface of the product. We use the correct tools and speed for your design. This saves your time and money.

-

Variety of materials

Now you can use the material that you desire. It will always be your choice! With this type of technique, you can choose from many materials at your disposal.

You must note that these materials should be hard enough for the process to take place without any problem. As manufacturers, we must use the same material that you require in their final product.

It makes it possible for CAD not to lose anything from its code.

Your choice comes first! We help you get the best raw material and process. CNC machining technology works on almost every material.

You must not worry about choosing the correct material. We’re always here for you!

We will help you find the best raw material for your end product to stand out.

You should first select a less expensive material. It will help you reduce the cost. Once the design is finalized, then you can go for the perfect material.

Aluminum is less expensive than other raw materials, and once the design is perfect, you can get it made in steel or any other material. This way, you will save your development cost.