Are you looking for a fast and accurate solution to producing parts and prototypes? Consider low-volume injection vowin.cn/en/News/news1251.html' target='_blank'>vowin.cn/' target='_blank'>molding as one of your options. This rapid prototyping technique is incredibly reliable and offers high precision, giving it an edge over other alternatives. But like any other technology, rapid injection molding has its disadvantages.

The pros and cons of low-volume injection molding

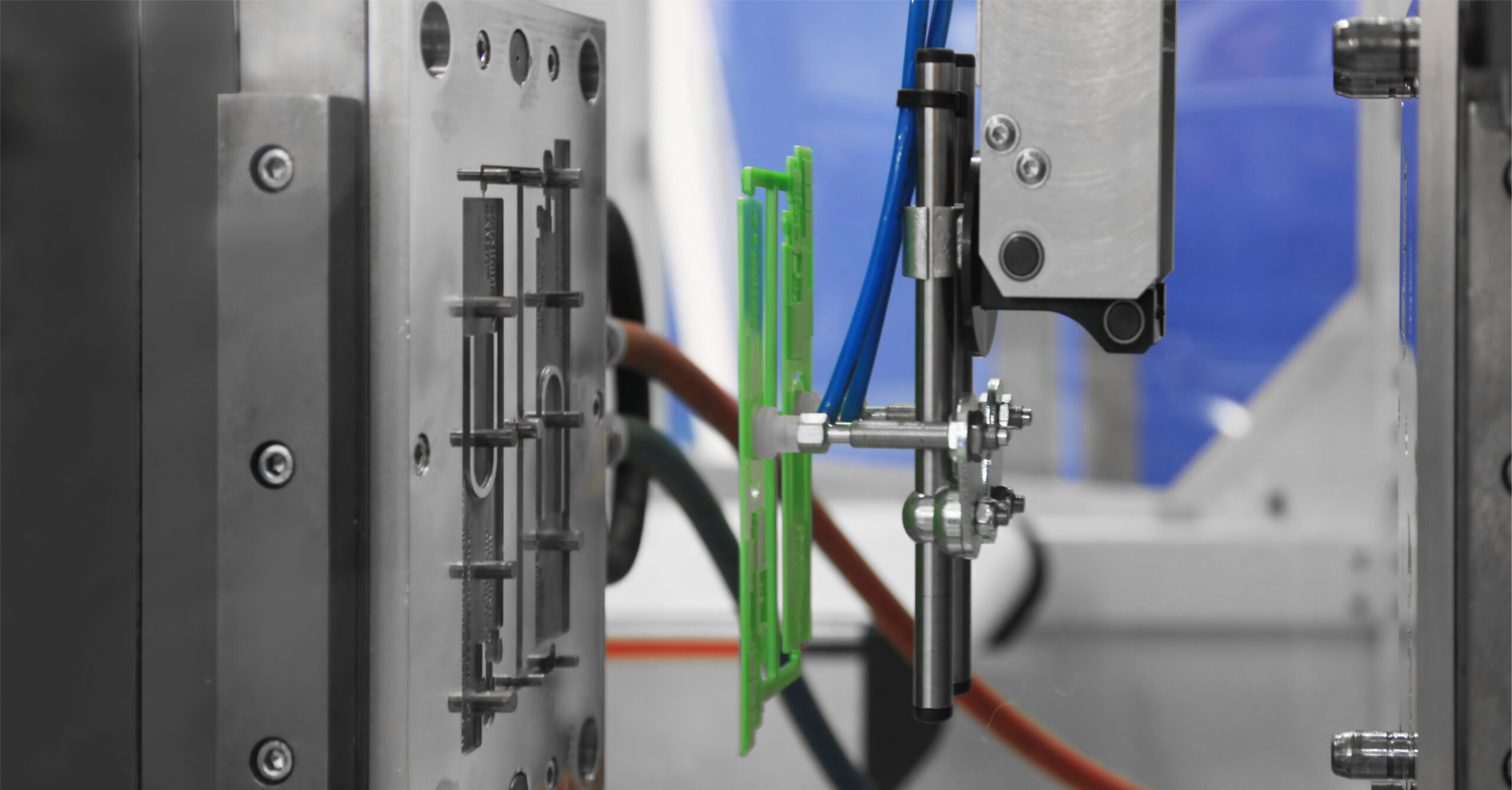

Rapid injection molding is a top choice for manufacturers producing highly detailed and intricate parts. This is because the technique allows you to add more features at smaller tolerances compared to other manufacturing processes.

For example, a miniature part can have bosses, ribs, metal inserts, holes, and more, all without compromising quality and integrity. Moreover, hundreds of identical products can be made thanks to injection molding’s high repeatability.

Depending on its complexity, a 3D-printed object can take up to 12 hours to complete. Subtractive manufacturing processes, such as CNC machining, can even take weeks.

Injection molding is significantly faster than these processes, with an average cycle time of ten seconds. The actual duration can vary depending on the complexity of your parts, but you will still be able to produce more objects in less time.

Thanks to its repeatability, injection molded parts and materials can be reused throughout several cycles. As a result, the process generates less waste, minimizing environmental impact.

Despite all that, low-volume injection molding does have its limitations. It allows you to create precise parts; however, to make this possible, you must plan everything from the start, incorporating details and features into your design. The design process can take time, and typically, you must go through several rounds of designing and modeling before getting the go-signal for production.

Is low-volume injection molding the right manufacturing process for your needs? Don’t forget to work with a trusted manufacturing service provider to ensure that the parts are produced according to your expectations.