The world of vowin.cn' target='_blank'>product design continues to undergo some fundamental and even revolutionary changes. Product lifespans are getting shorter and so is the expected time to market. As a result, product developers are moving away from mass production and towards the world of low-volume manufacturing.

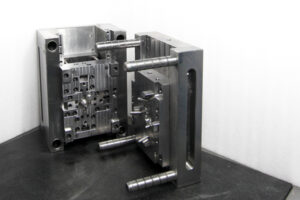

Star Rapid – Plastic Injection Molded Parts

What Is Low-Volume Manufacturing?

Low-volume manufacturing involves the production of 50 to 100,000 parts, acting as a bridge between one-off prototyping and full volume production. Here we want to explain some of the unique advantages that this service can provide to you.

The Top 4 Benefits Of Low-Volume Manufacturing

Low-volume manufacturing saves you money

Most people think it’s obvious that manufacturing costs per unit will go down as volumes go up. So if you want to make cheap parts, you should make more of them, right? Not necessarily. If you’re going to mass produce parts – especially for pressure die casting or injection molding – then you must make a larger investment in more expensive tool steel, which in turn needs to be hardened and heat treated more carefully to withstand the rigors of large-scale production.

With this in mind, low-volume manufacturing up to 100K pcs may be a great way for you to avoid a large investment while still producing high-quality parts. If the tool steel doesn’t need to be so durable then it will be more economical for you to purchase and faster for us to heat treat and machine. And, if your tool wears out during production and you need to have another one made, we do that at no extra charge!

By comparison, when a factory is set up for large-scale production it carries a massive inventory of raw materials and equipment. To cover their investment, they usually ask you to place a large minimum order quantity. But a specialist in low-volume manufacturing doesn’t carry the same amount of overhead so we can process orders faster and more economically without demanding any minimum order.

Star Rapid Manufacturing Tooling

Low-volume manufacturing ensures a faster time to market

As you know, the pace of technological change is increasing all the time and with it the constant demand to innovate. This puts product developers under very real pressure to create new designs or modify existing ones and get them distributed as soon as possible.

Being the first to market can be the difference between success and failure. Low-volume manufacturing is the ideal way for you to make enough volume to be sellable without creating an unsustainable burden of inventory. In addition, with optimized supply chains for low volumes, the lead times are short with parts ready to go in a matter of days or weeks – not months – so you’ll have a quicker route to market.

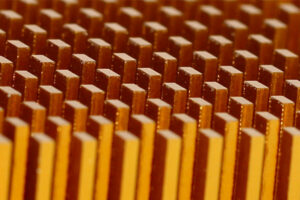

Star Rapid – Injection Molding Facilities

Low-volume manufacturing gives you design flexibility

During production, you may find some aspect of the design that you want to modify. Low-volume manufacturing lets you make those changes without greatly impacting the total order.

Team of engineers help with DFM

Low-volume provides an option for bridge production

Another benefit of low-volume manufacturing is that it provides a way for you to scale up to eventual full-scale production. That’s why it’s sometimes known as bridge production or bridge tooling. As volumes progressively increase, you have an opportunity to streamline best practices to achieve further cost savings while improving product quality.

Star Rapid – Finished Parts

How To Get Started On Your Next Low-Volume Project

As we race into the future the value that low-volume manufacturing brings to our customers will continue to grow. We know that low-volume manufacturing will increase in popularity as product life cycles become shorter and markets become more demanding. Learn more about the low-volume manufacturing facilities at Star Rapid or contact our team for a quote. Our engineers are ready to support you through the process.

rapid tooling prototype mold,prototype tooling, Low Volume Production ,prototype tooling,low volume mold, RIM Tooling