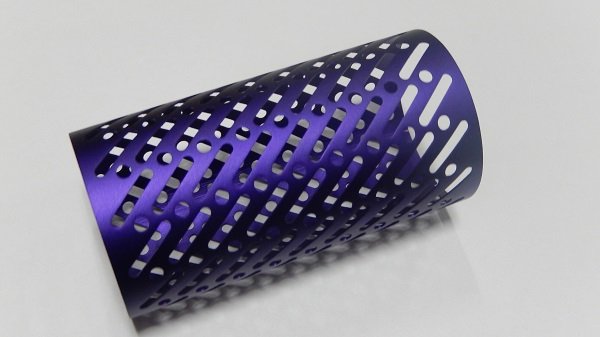

Before anodized of aluminum alloy, in order to make the Board more surface appearance, usually sandblast on the surface, sand flow using high speed impact to reduce surface roughness and form lines, anodized aluminum is a exquisite surface treatment.The Aluminum case is anodized with nature.

Sandblast should be uniform sanding pressure to be consistent and stable nozzle, spray angle to be consistent, the gun can not right in front of aluminum parts . Distance between nozzle and work piece is consistent.

Anodized aluminum may not be appropriate for all applications because of its non-conductive nature. Unlike other metals such as iron, the oxidation process doesn't seem to weaken aluminum. The layer of 'aluminum rust' is still part of the original aluminum and will not transfer to food or easily flake off under stress. This makes it especially popular for food-service applications and industrial applications where durability is crucial.