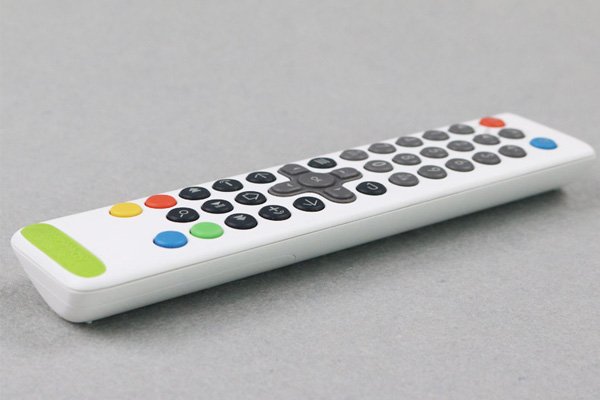

With the development of modern society, a variety of TV arise in the market. From the black and white TV to the present high-definition LCD TV, the TV remote control also become more and more upmarket.

The TV remote control prototype in the picture is ordered by a client from Wuhan, Hubei Province. Due to the long distance,client can not come to visit our factory. But our People sent some nice pictures of TV remote control prototypes we made before and our company introduction

PPT to clients. Client is impressed by our prototyping technique and decided to choose us to make the prototype for their product.

For this TV remote control prototype, do you know how to make it? Now, we’d like to introduce our prototyping making procedures to you.

1, Sales arrange production: After received the PO, sales will upload all the information including 3d files and 2d prints to OA system production department.

2, CNC Programming: the engineers will download the TV remote control drawings, then programming, after that they will send the program to CNC

vowin.cn/en/News/news1251.html' target='_blank'>

machining center .

3,

CNC machining : CNC machinist will download the designated program, then cut the material as required, finally CNC machine the prototype.

4, Polish :The surface finish department will debur and polish the parts, then will start polishing and test assembly

5, Surface finish: for TV remote control prototype, we do painting and silk-screen for these parts.

6, Quality control : When all parts finished, the QC department will test the prototype parts as per clients’ 3d files and reassemble. Once all parts are qualified, the parts could be packed up and shipped out to clients .