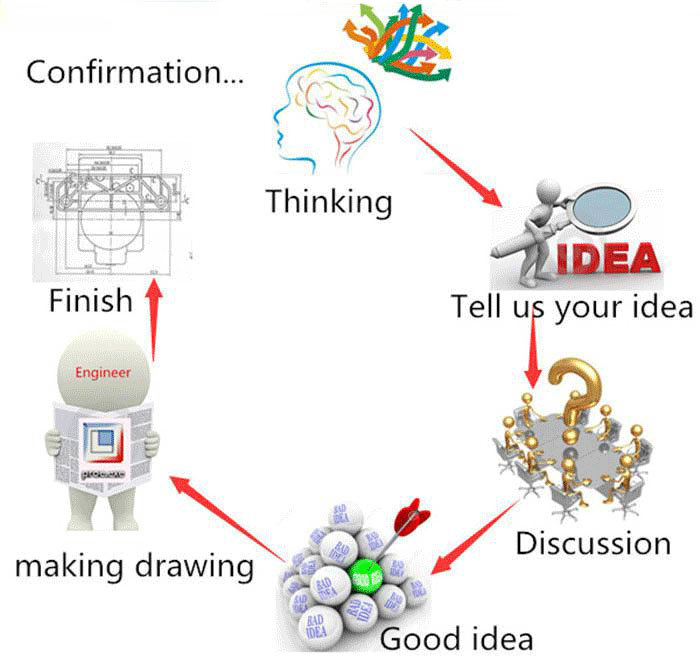

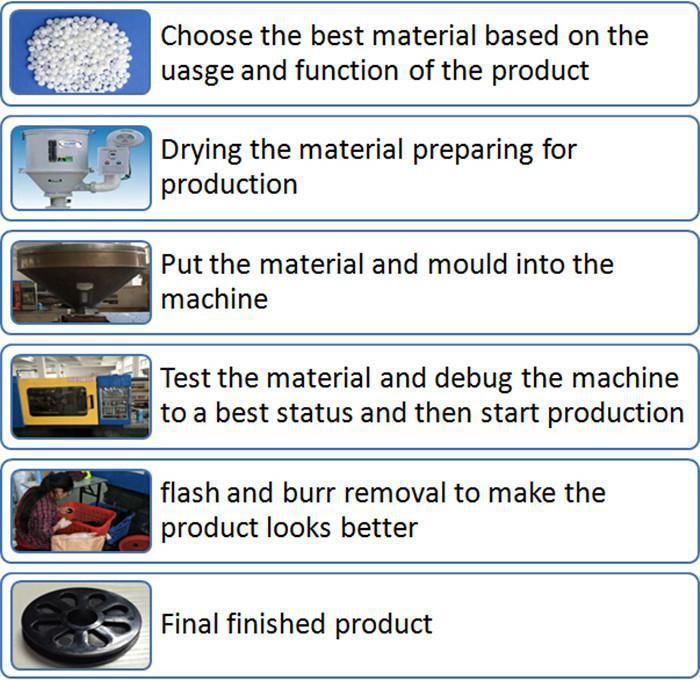

4 steps to deal with your project

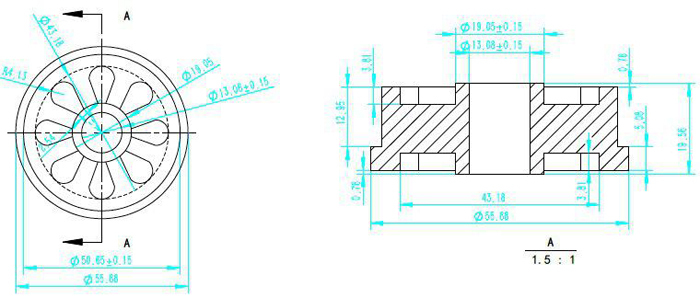

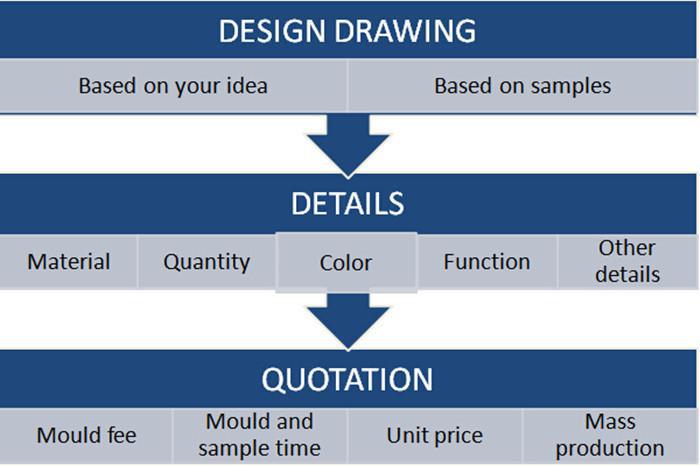

I.Tell us your idea or send us your samples,we can make drawings

II Quotation based on drawings and other important details including use,material,color,quantity etc.

III.Making samples for you to check.if there is any parts need to change,we can revise the mould.

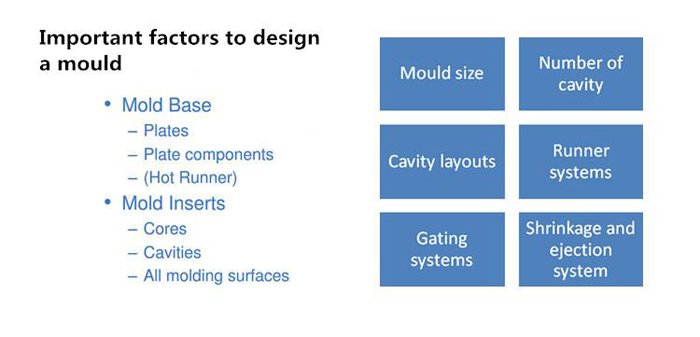

| The Introduction of Mould | |

| Mould material | P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc . |

| Mould type | Injection plastic mould |

| Product material | ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE,etc |

| Mould base | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mould runner | Hot/Cold Runner |

| Mould tooling equipment | Lathe,Milling,Grinder,Drill,CNC,EDM,Wire cut machine,Punch machine |

| De-mould Type | Automatic Ejector |

| Maximum mould size | 1500*1500 mm |

| Gate | Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc. |

| Cavity | Single or Multi cavities |

| Mould Life | 45#:300,000 to 500,000 shots |

| P20:600,000 shots | |

| 718: 800,000shots | |

| Lead time | About 3-4 weeks |

| Package | Wooden packing box or as customer's requirements |

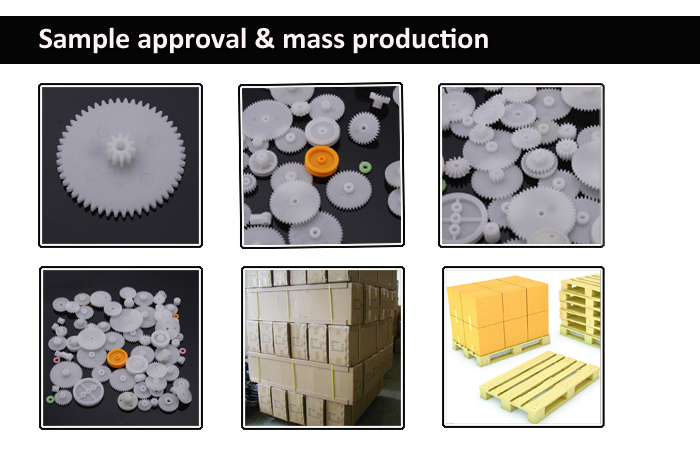

IV. Making samples for you to check. if there is any parts need to change,we can revise the mould.

V.Mass production after samples approval and arrange delivery