When you want accuracy and precision in your prototyping services, you can use internet search engines to search for some valid information about a variety of tools that can help you to make the prototype’s shape accurate and precise. Some prototyping companies are making big size prototypes while are some designed to produce tiny prototypes, yet not all of them are capable of delivering 100% accuracy.

Though there are many ways that sheet metal can be cut and shaped, not all of them are as cost-effective and reliable as a laser cutting tool which also delivers utmost precision. Laser cutting tool is equipped with advanced technology which makes it that much effective that the improvement and continuation of its future capabilities are inevitable.

Laser cutting Tools: Categories-

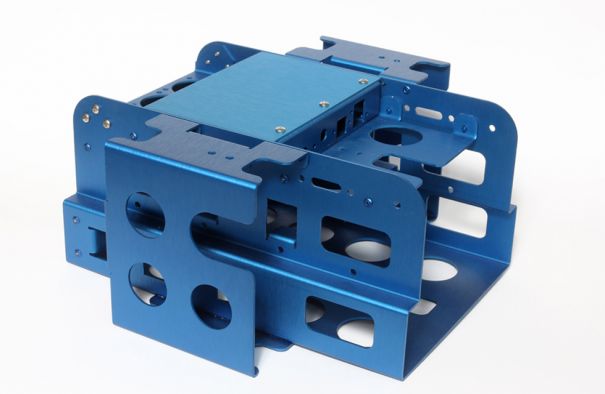

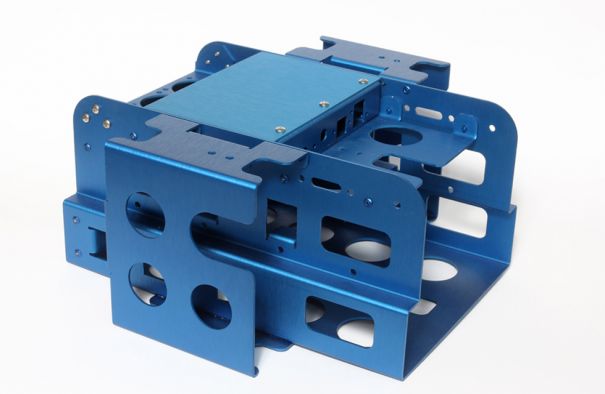

Laser cut is a versatile tool that can be used to cut and shape a variety of materials for example; glass, plastic, wood,

sheet metal prototype, and even stone.

· A CO2 laser is a popular type of cutting tool which is widely used due to its easy control and high accuracy. In this, to fuel the cutting, a laser beam made of concentrated CO2 gas is activated by electricity.

· A fiber laser typically utilizes glass fibers to strengthen a seed laser’s potential effectiveness. As a result, it becomes a sharp laser that is both powerful and precise, especially more than a CO2 laser. A fiber laser is usually used for sheet metal prototyping as the laser beam here is focused and intense.

· A crystal laser is not very different from a fiber laser, but what makes it a little different is that it uses both crystals and pump diodes to generate the intensity of its beam. A crystal laser has application and performance potential, comparable to a fiber laser.

There are many reasons behind the usage popularity of laser cutting as the preferred method when making a sheet metal prototype and a few of the reasons are described below.

There are many reasons behind the usage popularity of laser cutting as the preferred method when making a sheet metal prototype and a few of the reasons are described below.

· Detailed results are possible: Since the laser has an average size of a few micrometers, it allows precision to make and cut sheet metal prototypes that might have been impossible using other methods. As a result, it offers a limitless array of possibilities.

· Scalability: The laser cutting tools let the companies cut as much or as few prototypes as their customers require. These lasers generally don’t require adjustments and retooling to adapt the design of a specific piece. Since adjustments are inevitable, they are easier to achieve through a laser cutter.

· Properly finished edge: Utilizing a sold and physical technique, for instance, a blade to cut metal sheets results in inappropriate shape, roughness, imperfections, and burrs along the edge. For many designs, they would require being buffed out or removed which can increase the time it takes for the end user to receive their products. Utilizing laser cutting toll would eliminate this problem.

As of right now, CO2 lasers are still leading the industry standard and fiber lasers are rapidly being adopted. Although fairly new, the fiber laser technology is projected to become standard over the next couple of decades.