Many companies generate their prototypes and industrial parts through vacuum casting. It is a quick and effective method to make high-quality parts and design samples in small quantities. Using reusable silicone vowin.cn/' target='_blank'>molds and melted casting resins, it can make a perfect copy from the master pattern.

The end-products in vacuum casting are used in many ways, including in product development, engineering testing, and product displays for marketing campaigns. Here is a look at how vacuum casting can benefit companies in their product development.

The Vacuum Casting Process

The initial step in vacuum casting is the preparation of the master pattern. This master pattern is a prototype that is made from a durable and solid material. CNC machining or 3D printing is usually used on making the master pattern because these methods are fast and can easily accommodate the changes in the design if necessary.

This master pattern is carefully prepared using sanding, polishing, and even painting to perfect the surface finish.

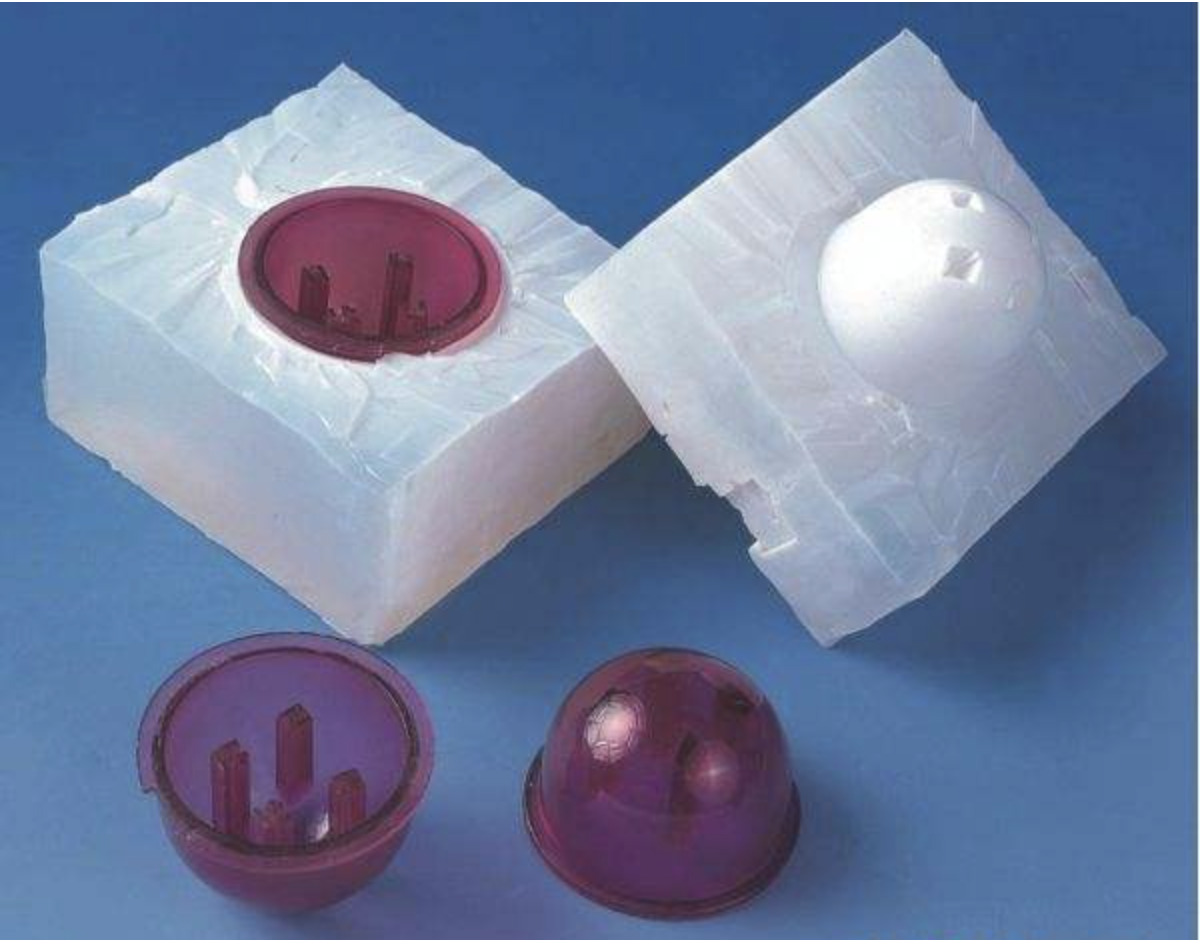

Once this master pattern is ready, it is put inside the casting box and covered with the liquid silicone. It's cured in the oven, and once it becomes solid, it will be taken out. This mold is carefully cut in its seam line, and the pattern is removed. What you have is an empty cavity that reflects the original.

The production starts by resealing the mold, and a feed tube is added that leads to the cavity. This is filled with the liquid urethane resin and put inside the vacuum chamber. This vacuum will remove the air from the cavity, thereby eliminating the bubbles and forcing the resin to fill the empty chamber. Opening the mold will reveal a replica of the pattern.

Why is Vacuum Casting Preferred in Prototyping?

Manufacturers prefer vacuum casting due to the following advantages.

1. Its end products have great quality. Because the master pattern is finished to perfection, you can expect nothing less from vacuum casting when it comes to quality. The succeeding replicas do not veer away from the original.

2. It is fast. Comparing it with other means of prototyping that uses tooling made from steel, silicone molds are faster to prepare and will take only days. This is particularly helpful when working on a tight deadline, and you have to make prototypes fast.

3. It offers greater versatility. Although there are many ways to build prototypes, only vacuum casting can create the feel, look, and performance of a product using different materials like ABS, nylon, or polyethylene. It does not sacrifice functionality in the name of speed and convenience.

4. It is cost-effective. When the master pattern is made, the vacuum casting method is the most cost-effective way to make high-quality duplicates. There is not much investment necessary for hard tools, like in pressure die casting and injection molding. You can invest the money in other product development or design iterations.