Vowin Changes The Prototyping Scene For Joost Engines

Joost Engines Ltd is an innovative company in the U.K. in the process of designing and prototyping a novel engine. Joost Engine design internal combustion engines/outboards that are a third of the weight as traditional ones but have the same power.

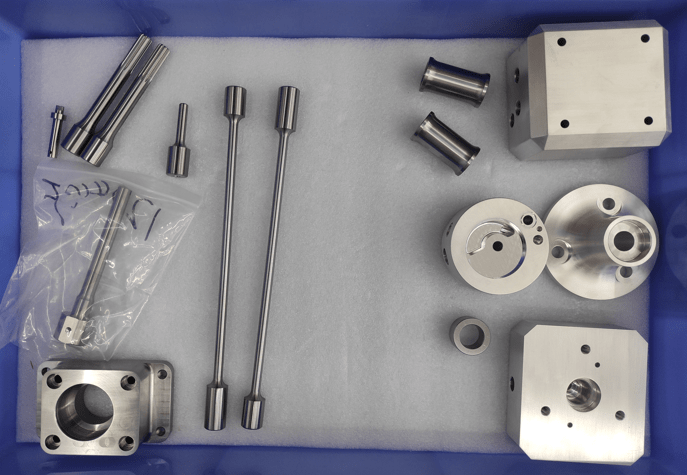

Typical project Example

Project: Deliver 16 individual CNC machined parts

Materials and Finishing: Steel and aluminium with a deburr finish

Manufacturing Time: 15 days

Client Story

Joost Engines is an innovative company in the U.K. in the process of designing and prototyping a novel petrol engine and are frequently designging and testing prototype components for their engines. These components include crank, driveshafts, flywheels, bearing, oil pump, etc. All of which are manufactured from a wide range of materials.

Joost Engines first engaged Vowin back in 2019 to provide precision components for their engine development and testing programme. Since then, Joost Engines has relied on Vowin for CNC Machined and SLM (metal) 3D printed prototypes.

“All components have been shipped to specification, +/- 10 microns in some cases for bearings, with a measurement report available for all the items. We have been delighted with speed and consistency of delivery,” said Paul Adlem, director of Joost Engines.

“We’ve found that Vowin have a can-do positive attitude and they have met our high demands for both quality and delivery for a wide range of challenging components.” – Paul Adlem, Director, Joost Engines Ltd

Traditionally, custom machined parts can take between 5 to 6 weeks or longer to be delivered. Despite the prototypes being manufactured and post-processed in Vowin’s China facility then shipped, “Vowin have provided components within 3 weeks to the U.K. without fail,” said Paul.

“The positive impact that Vowin’s delivery reliability has had on our development and testing programme has been positive game changing.” – Paul Adlem, Director, Joost Engines Ltd