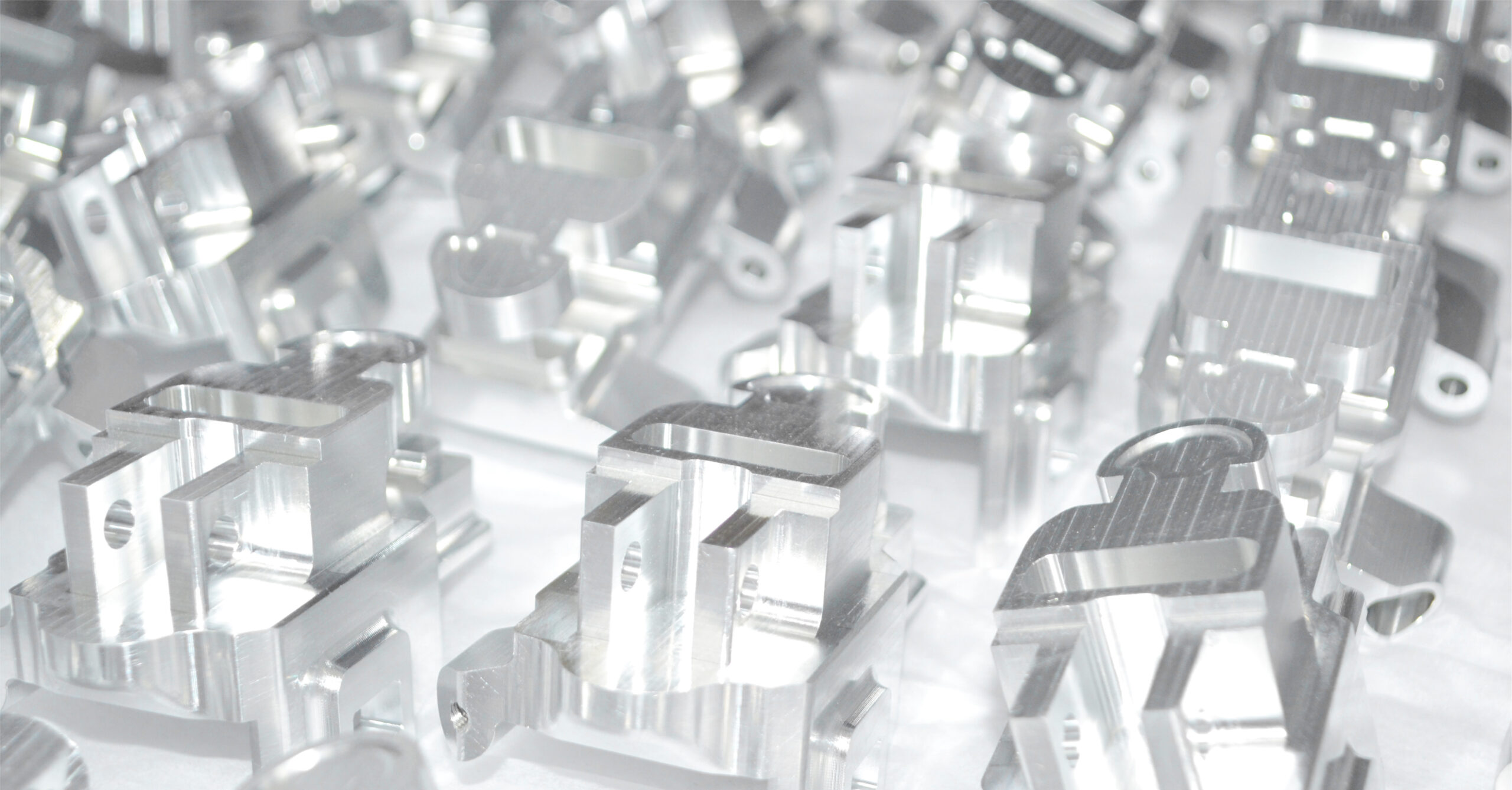

Companies like Vowin Prototypes

offer efficient and economical CNC prototyping services

in China,

expediting the creation of your design’s physical model.

Regardless

of whether you require functional or aesthetic models,

we

can

meticulously deliver them according to your specifications. We adhere

to ISO 2678-1 standards for tolerance control and collaborate closely

with you to plan the manufacturing process.

Are you considering CNC vowin.cn/en/News/news1251.html' target='_blank'>machining to build prototypes? You might

wonder why it’s better to outsource it to a specialist like Vowin Prototypes. With our CNC prototyping services,

you have

access to industry experts who can deliver high-precision, robust parts fast.

Our service starts with a free project review, so we can determine if CNC machining is the right solution.

Otherwise,we can suggest other rapid prototyping services we have, such as 3D printing and injection

molding. With us

as your prototyping partner, you do not have to worry about wasting time and money on your project.

The benefits we bring

Our CNC prototyping services in China can add value to your project with these benefits:

Accuracy

Our CNC-machined parts are controlled to the tightest tolerances to ensure precise and accurate parts

according

to your specifications. Plus, we can support your CAD design process with design tips, like ensuring the

hole

depth diameter ratio won’t exceed 10:1. That way, we do not have to drill further.

Speed

Vowin Prototypes can finish your parts within a few days or weeks, depending on their complexity.

Once your CAD model is ready, we will get right to work. Based on your project’s needs, we will

configure the best seriesof drill bits and tools to cut away at the block of metal or plastic. We are

confident that we can delivercustom CNC prototyping services in China fast using our range of

50 CNC mills, multi-axis machines, surface grinding

machines, sink and wire EDMs, and lathes.

Leave your prototypes to us.

At Vowin Prototypes, we can make at least 1 CNC-machined part, but we can configure our

manufacturingprocess to accommodate low-volume production of up to 100,000 identical

components. Contact us today

for a free project review.