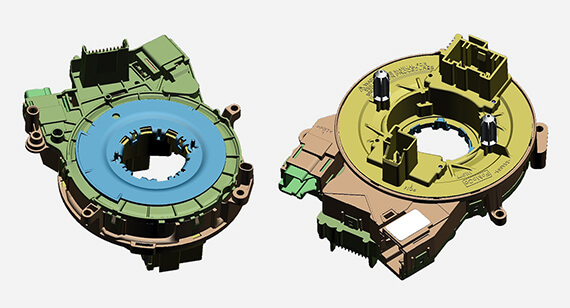

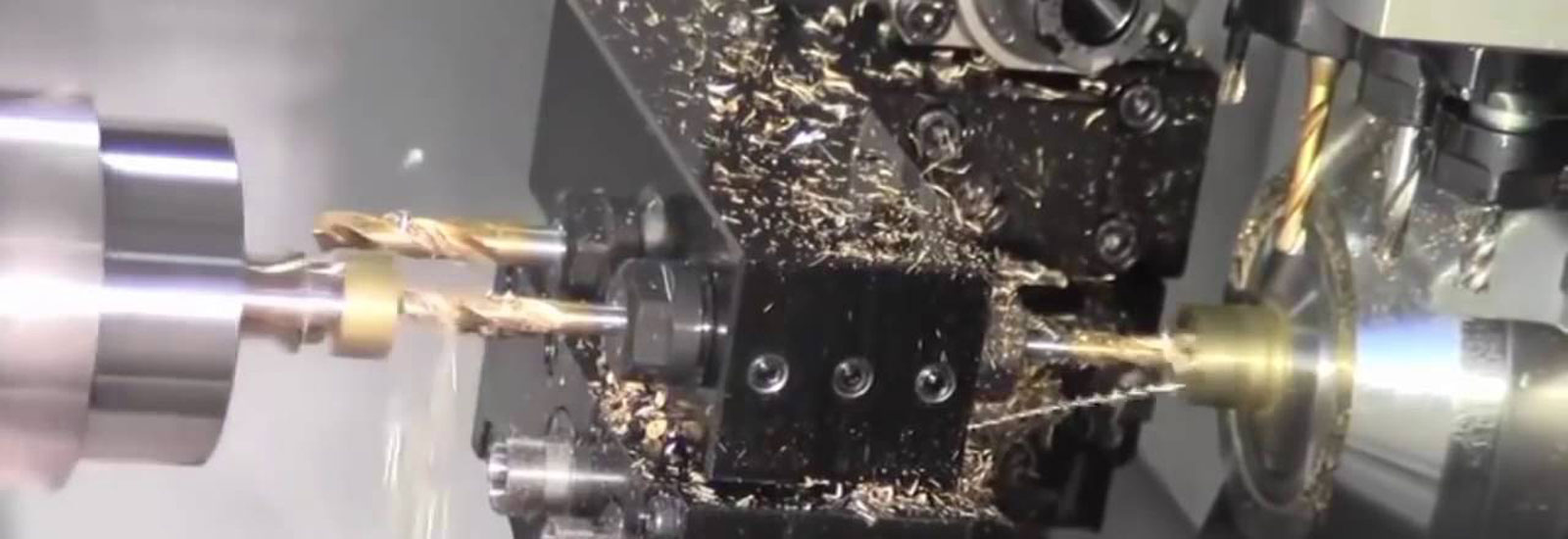

Nice Rapid Limited has been providing CNC Milling Service China for international customers for over a decade. As a ISO 9001 & ISO 14001 certified CNC Milling Service China factory, all our processes are carried out through hundreds of advanced CNC Machining machines, lathes, and other manufacturing facilities, ranging from blasters to Ultra Sonic washing machines. Our CNC Milling Service China Center not only has advanced equipment but also have a professional team of experienced engineers, operators and inspectors to make the customer’s design come true.