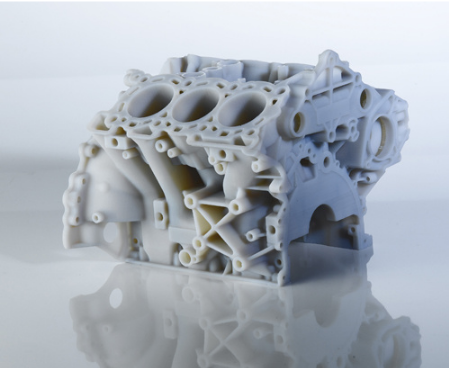

Rapid prototyping is a good procedure of software development in which physical things are automatically constructed by regular use of SFF or solid freeform fabrication. In the process of Rapid Prototyping, a working model can be constructed quickly, and tested for its functionality, performance as well as output. The latest features or information can be illustrated well in the prototype as well as early user feedback can be gathered with regards to the manufactured goods.