In the first article of this series, we addressed the material thickness, bend radii, flange lengths, and K-Factor features that designers should consider when producing sheet metal designs. In this article, we will look at further features and limitations typically encountered when designing sheet metal components.

Bend Relief

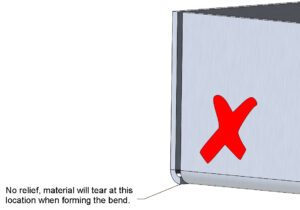

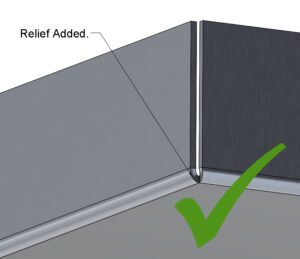

When producing a part with adjoining bends, special cuts must be made into the part to prevent material near the bend from tearing during the bending process. See below an example of an un-manufacturable bend with no relief and a part that has relief accounted for.

No Relief sheet metal part design

releif added, sheet metal part design

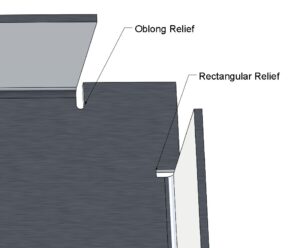

For bends where the flanges aren’t adjoining, there are a number of different relief types available for utilisation by designers, two of the most common types are shown below. Note that a good rule of thumb to follow for relief cut sizing is for the width to be at least the thickness of the material and for the length of the cut to exceed the radius of the bend.

releif sheet metal part design

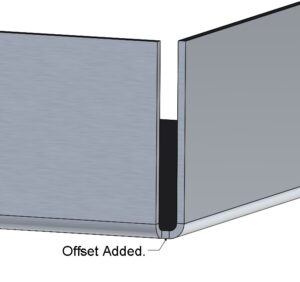

See below an example of a flange that has been offset to avoid the need for a relief cut.

offset added sheet metal part design rules

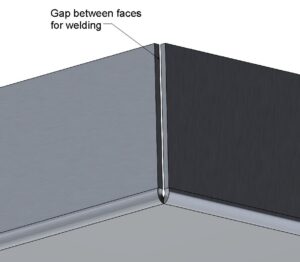

It is important to consider whether the flange corners are to be closed or not, they may require a gap to allow for welding.

weld gap sheet metal part design rules

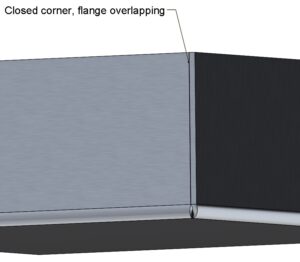

With the corners closed, there is still the option to weld the flanges together on the inside faces if required.

sheet metal part design rules flange overlap

Hole Features

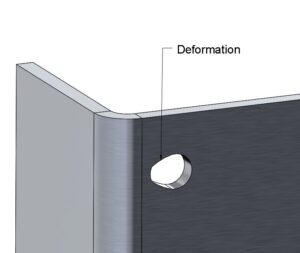

Holes and slots which are dimensioned close to bends are susceptible to deforming following bending, see an example below of how a hole may appear the following bending if it is positioned too close.

sheet metal hole design rules

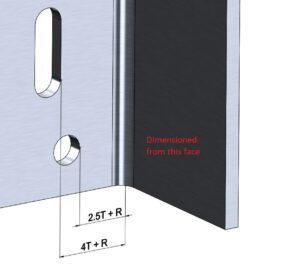

To prevent this deformation, the minimum dimension for hole and slot edges from the bent edge should be applied as follows.

sheet metal hole design rules

Minimum hole edge from bend face = 2.5T + R

Minimum slot edge from bend face = 4T + R

Where T is the material thickness and R is the bend radius.

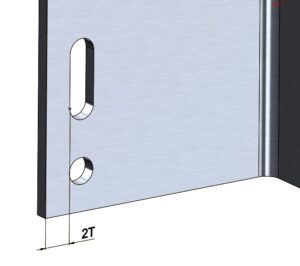

Ensure that holes and slots are positioned at least twice the material thickness from any material edge as shown below.

sheet metal hole position design rules

Edge Treatments

Some components benefit from having special features formed from the remaining edges, two of these main features are curls and hems.

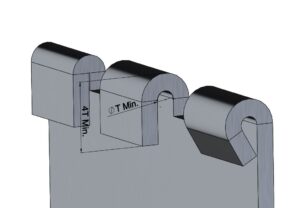

Curls are circular rolls formed from the edge, these provide extra strength to the edge and also make it safer for handling by removing the sharp edge. The outer radius of a curl should be at least twice the material thickness, although this will vary depending on the manufacturer and their tooling for curling.

curl edge treatment, sheet metal design rules

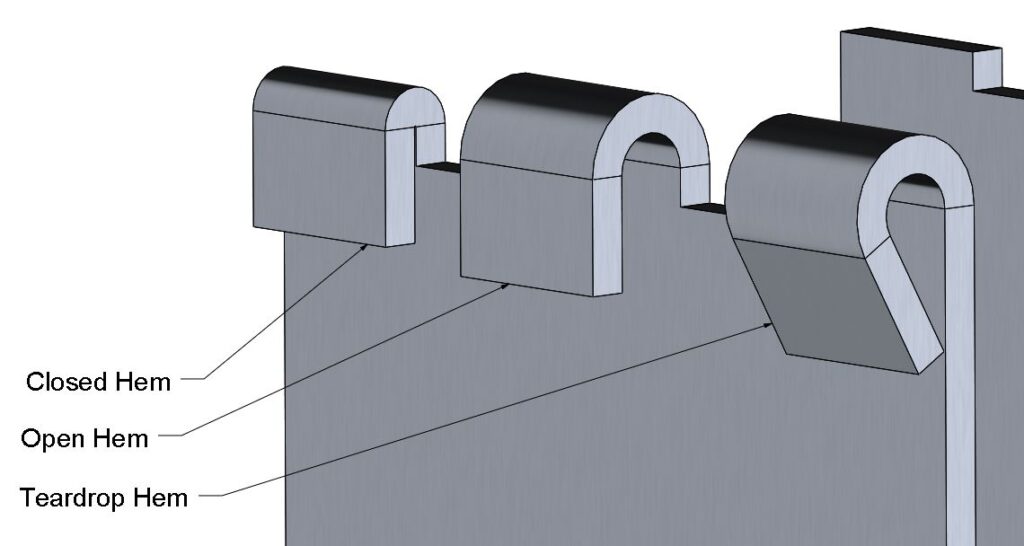

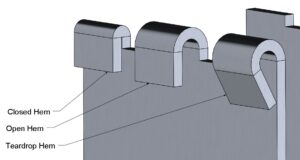

Hems are similar to curls but are formed into a U shape. They are useful for strengthening edges and can be used to connect parts together. There are three main types of hem, an open hem, a closed hem, and a teardrop hem.

edge treatment, sheet metal design rules – hems

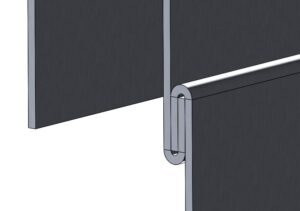

More press tonnage is required to create the closed hem. See an example below of how open hems can be used to connect two parts.

hem assembly edge treatment, sheet metal design rules

Minimum dimensions for hems will vary between manufacturers, the following dimensions are for general guidance.

For open hems and teardrop hems, the minimum inside diameter should be at least the material thickness. For all hems, the return length should be at least 4 times the material’s thickness.

edge treatment, sheet metal design rules