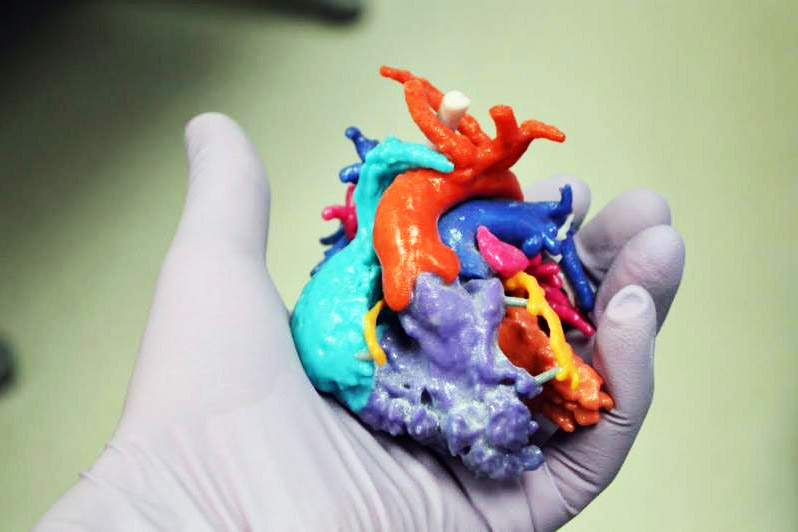

HeartPrint cardiovascular model from Materialise

The use of additive manufacturing applications is on the rise, with the market value expected to increase from $6 billion in 2017 to nearly $26 billion by 2022.

The advantage of additive manufacturing comes from creating complex structures that vary in complexity, customization, light weight, strength and speed. As additive manufacturing for medical devices continues to gain momentum, there are five main areas where we are seeing the most growth opportunity from this evolving technology. Let’s take a look at how the capabilities of additive manufacturing have become the de facto method of production in these industries.

The largest market for additive manufacturing in medicine right now is dentistry and related orthodontics such as bridges, crowns, braces and dentures. Currently, digital dentistry is a $2.5 billion industry and this is set to more than double in a few years.

Digital dentistry is more of a workflow than a single technology. This process typically begins with a scannable model or impression that’s subsequently converted into 3D digital data.

Many 3D printed dental appliances are easily customized for a precise fit while also being printable in a variety of substrates, from flexible polymers to rigid titanium.

Dentures from EnvisonTEC

There are also specialized printers configured to use dental scanning software, along with biocompatible resins, that can fit in small offices and clinics for immediate, on-the-spot solutions ready in a single day.

The human body is complex and each is unique. Therefore, when doctors and clinicians need to consider individual treatments, it helps enormously to see an accurate model of the subject in question – whether that’s a bone, an organ, a tumor or a limb.

3D scanned and printed anatomical model for study

Luckily, this is now a reality. Great strides have been made in medical imaging technology, including highly accurate full-color 3D scanning down to the vascular level. Using this data, along with sophisticated topological mapping software such as Mimics®from Materialise, biomedical engineers can use 3D printers to create realistic models for analysis.

From these models, doctors can then devise surgical strategies like where to make incisions. Also, models assembled from multiple pieces can be disassembled to reveal structures within that might otherwise have been blocked from a surgeon’s view. The number of hospitals in the United States with a centralized 3D printing facility has grown exponentially, from three in 2010 to more than 100 by 2019.

This is a broad category of auxiliary equipment that would be expensive and time-consuming to develop in smaller volumes. It includes clamps or grips designed for an individual patient’s anatomy, possibly to aid in examinations, treatments or surgical procedures.

3D printed parts from iLab/Haiti

Additive manufacturing applications are also being used in many developing countries to design non-specific clamps, catheters and other fittings that are fast and economical to produce on the spot as needed.

Additive manufacturing technology has helped expand patient options for prosthetics and orthotics in terms of fit, function and aesthetic. A prosthetic can be a replacement of a body part, either internally (i.e., hip joint) or externally (i.e., a missing limb).

Taiwanese girl with 3D printed articulated prosthetic

Traditionally, prosthetic limbs were inadequate in their customization options. They were either limited in their functionality or incredibly expensive, requiring a lot of measurement, test fitting and hand-craftsmanship that is inaccessible to many people. This is especially true in remote areas or regions experiencing military conflict, where such prosthetics are in high demand.

Orthotics are also custom pieces, made to assist the wearer’s bone structure with extra support or by correcting misalignment issues. Using modern polymers, 3D printed plastic orthotics are strong, lightweight, durable and also pliable for added comfort. They can also help mitigate foot pain caused by conditions such as diabetes, arthritis or plantar fasciitis.

Another advantage of additive manufacturing for medical devices is the ability to make complex micro gadgets that work inside the body to deliver medicine or to monitor a patient’s health.

MIT, in conjunction with Harvard’s Brigham and Women’s Hospital, has developed an ingestible device that can remain in the stomach for a month. Self-powered, it delivers discrete amounts of drugs for patients requiring long-term care, including those who require treatment for cancer or HIV. This device is currently in the testing stage, but it represents the kind of approach that many other researchers are trying to refine.

Such micro devices will soon be able to transmit data wirelessly to an external medical wearable for detailed health monitoring. Other printed sensors can be injected into the bloodstream to provide active monitoring of blood glucose levels, blood oxygenation and other critical metrics that doctors will use to quickly respond to a patient’s medical condition.

These are just a few of the amazing applications being made with this transformative additive manufacturing technology.

Interesting in learning more about medical manufacturing? Read about…